កុម្ភៈ . 15, 2025 12:11

Back to list

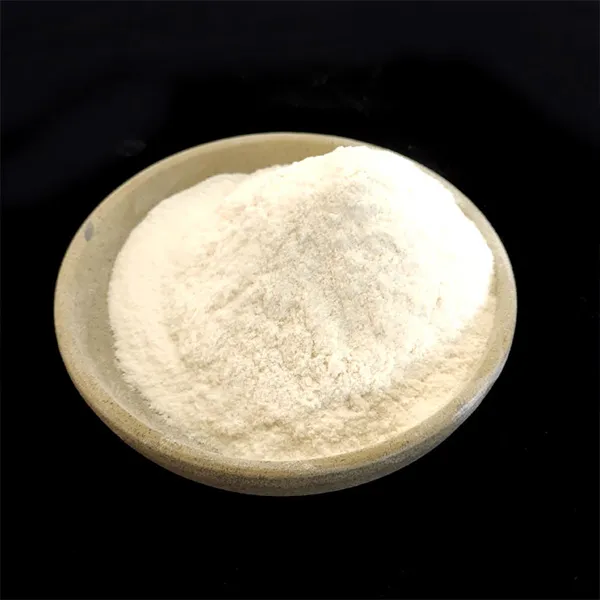

grade cellulos

Understanding the intricacies of grade celluloses can be pivotal for industries spanning from pharmaceuticals to food production. With the constant evolution of manufacturing technologies and consumer demands, grade cellulose has emerged as a versatile component in various product formulations.

Authoritativeness is derived from comprehensive research and technological advances in cellulose grading. Laboratories around the globe are consistently exploring and developing novel cellulose derivatives that meet stringent quality standards. These derivatives offer improved solubility, thermal stability, and non-reactivity, making them suitable for complex industrial applications. Such authority in the domain elevates the reliability of cellulose-based products, reinforcing confidence among manufacturers and consumers alike. Trustworthiness is an essential pillar when considering the deployment of grade cellulose in product formulations. Certified suppliers and quality audits play a crucial role in ensuring that only the highest grades are utilized. This systematic approach prevents contamination or substandard material from entering the production line, safeguarding both the end-user and the brand's reputation. Furthermore, transparent documentation and compliance with international standards bolster trust in cellulose products, making consumers more inclined to choose them over alternatives. Grade celluloses, therefore, represent more than just another ingredient; they symbolize a commitment to quality, safety, and innovation. The nuances of grading allow industries to tailor products that are not only efficient and effective but also sustainable and environmentally friendly. As the demand for such versatile materials grows, so does the importance of staying informed and up-to-date with the latest advancements in cellulose technology. Whether you're in pharmaceuticals, food production, or any industry that values high-quality material input, understanding and utilizing grade celluloses can significantly enhance the calibre and reputation of your products.

Authoritativeness is derived from comprehensive research and technological advances in cellulose grading. Laboratories around the globe are consistently exploring and developing novel cellulose derivatives that meet stringent quality standards. These derivatives offer improved solubility, thermal stability, and non-reactivity, making them suitable for complex industrial applications. Such authority in the domain elevates the reliability of cellulose-based products, reinforcing confidence among manufacturers and consumers alike. Trustworthiness is an essential pillar when considering the deployment of grade cellulose in product formulations. Certified suppliers and quality audits play a crucial role in ensuring that only the highest grades are utilized. This systematic approach prevents contamination or substandard material from entering the production line, safeguarding both the end-user and the brand's reputation. Furthermore, transparent documentation and compliance with international standards bolster trust in cellulose products, making consumers more inclined to choose them over alternatives. Grade celluloses, therefore, represent more than just another ingredient; they symbolize a commitment to quality, safety, and innovation. The nuances of grading allow industries to tailor products that are not only efficient and effective but also sustainable and environmentally friendly. As the demand for such versatile materials grows, so does the importance of staying informed and up-to-date with the latest advancements in cellulose technology. Whether you're in pharmaceuticals, food production, or any industry that values high-quality material input, understanding and utilizing grade celluloses can significantly enhance the calibre and reputation of your products.

Next:

Latest news

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025