The Importance of HPMC Mortar in Modern Construction

In the domain of construction materials, HPMC (Hydroxypropyl Methylcellulose) mortar has emerged as a vital component, gaining recognition for its unique properties and functional benefits. As the construction industry evolves, so does the need for innovative materials that can enhance performance and durability. HPMC mortar offers a solution that addresses these demands, making it invaluable in both residential and commercial building projects.

What is HPMC Mortar?

HPMC is a cellulose ether derived from natural cellulose fibers. It is modified to provide specific performance characteristics that improve the properties of mortar. When added to cement-based materials, HPMC significantly improves their workability, adhesion, and water retention capabilities. These enhancements contribute to the overall quality and longevity of construction projects, making HPMC mortar a preferred choice for many contractors and builders.

Benefits of Using HPMC Mortar

1. Enhanced Workability One of the standout features of HPMC mortar is its excellent workability. The addition of HPMC allows for a smoother mixing process and easier application. This characteristic is particularly beneficial in complex architectural projects where precision in placing mortar is essential. Workers can achieve a consistent texture, making it simpler to apply the material evenly.

2. Improved Adhesion HPMC mortar exhibits superior adhesion to various substrates, including brick, concrete, and block surfaces. This strong bond ensures that the materials remain securely in place, reducing the likelihood of cracks and structural failures. This quality is especially crucial in areas subject to dynamic loads or environmental stressors.

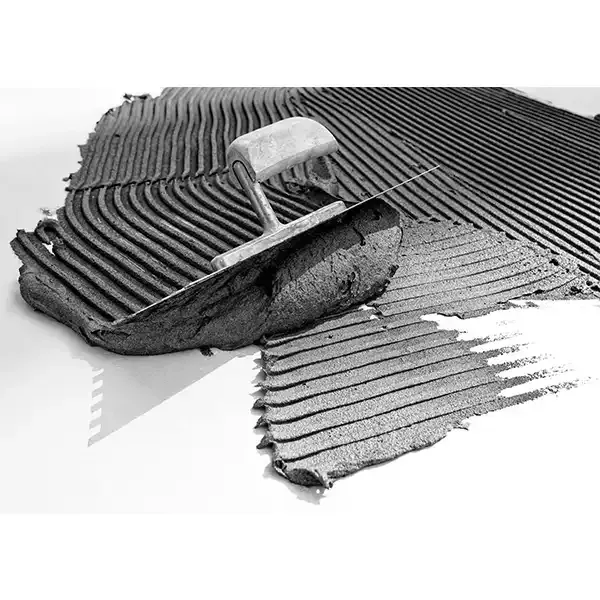

hpmc mortar

3. Water Retention In construction, the proper hydration of cement-based materials is essential for achieving optimal strength and stability. HPMC improves water retention in mortar mixes, allowing them to remain workable for longer periods. This feature is particularly advantageous in hot or windy conditions, where moisture loss can lead to premature setting and reduced performance.

4. Reduced Shrinkage Cracking Mortar containing HPMC tends to exhibit lower shrinkage upon curing compared to traditional mortar. This characteristic helps mitigate the risk of cracking, which can compromise the integrity of the structure. By reducing shrinkage, HPMC mortar enhances the durability and lifespan of the building.

5. Versatility HPMC mortar is suitable for various applications, including tile adhesion, wall structure bonding, and plastering. Its versatility allows it to be used in both interior and exterior projects, making it a go-to material for builders looking to optimize performance across various construction tasks.

Conclusion

As the construction industry continues to seek out materials that meet modern demands for efficiency, durability, and sustainability, HPMC mortar stands out as a significant innovation. Its remarkable characteristics not only enhance performance but also contribute to the longevity of structures built with it. With its ability to improve workability, adhesion, and water retention, HPMC mortar has become a staple in contemporary construction practices.

In an era where building standards are continually rising, embracing materials like HPMC mortar is essential for builders aiming to deliver high-quality, lasting constructions. Whether in residential homes, commercial buildings, or infrastructure projects, the application of HPMC mortar can lead to better outcomes, ensuring that structures withstand the test of time and environmental conditions. As we look to the future of construction, the importance of HPMC mortar will likely continue to grow, driving innovation and excellence in building practices worldwide.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025