កុម្ភៈ . 14, 2025 15:34

Back to list

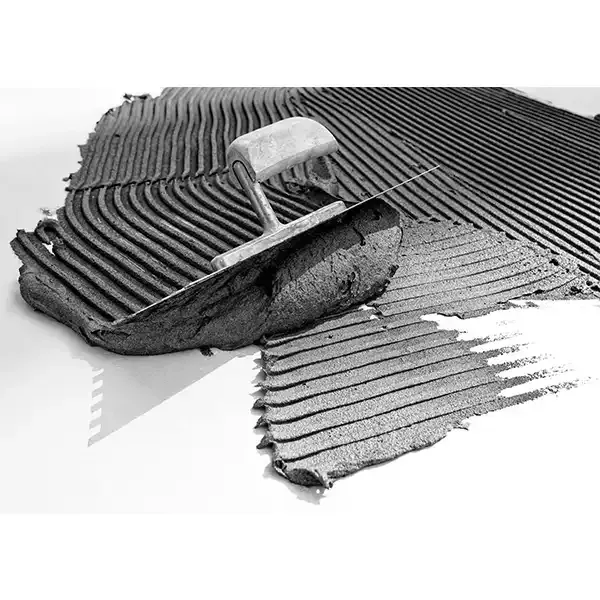

hpmc mortar

Enhancing construction materials with modern innovations often leads to significant improvements in durability and performance. One such innovation that is garnering attention is HPMC mortar. HPMC, or Hydroxypropyl Methylcellulose, is a versatile polymer used as an additive in mortar, offering myriad benefits that improve construction outcomes. As an expert in construction and material science, my professional encounter with HPMC mortar has consistently reinforced its invaluable contribution to building integrity and efficiency.

From a sustainability perspective, the use of HPMC in mortars aligns well with modern eco-friendly construction practices. By refining the efficiency of raw material usage and reducing wastage due to rework or defects, HPMC contributes positively to resource conservation. Environmental benefits coupled with economic advantages make HPMC mortar an attractive choice for projects aspiring to adhere to green building standards. Trustworthiness and reliability are paramount in any construction material, and HPMC mortar does not disappoint. Backed by comprehensive research and decades of industry testing, its performance is both measurable and predictable. Its ability to withstand various stress factors over time has been documented in numerous studies, reinforcing its status as a reliable choice for a range of construction needs. Experts in the field recognize that continuing advancements in material science offer solutions that can greatly extend the lifespan and usefulness of construction materials. With industry-recognized certifications and a strong track record in diverse applications worldwide, the authority of HPMC mortar is well cemented in both practical and theoretical realms. In conclusion, the practical experience and extensive expertise surrounding HPMC mortar attribute to its growing popularity in the construction industry. Its ability to improve workability, enhance durability, ensure proper adhesion, and support sustainable practices makes it an authoritative and trusted component of modern construction methodologies. As building innovations continue to evolve, HPMC mortar stands out as a pioneer in redefining how we think about building materials, ensuring structures are not only built to last but are also economically and environmentally sound.

From a sustainability perspective, the use of HPMC in mortars aligns well with modern eco-friendly construction practices. By refining the efficiency of raw material usage and reducing wastage due to rework or defects, HPMC contributes positively to resource conservation. Environmental benefits coupled with economic advantages make HPMC mortar an attractive choice for projects aspiring to adhere to green building standards. Trustworthiness and reliability are paramount in any construction material, and HPMC mortar does not disappoint. Backed by comprehensive research and decades of industry testing, its performance is both measurable and predictable. Its ability to withstand various stress factors over time has been documented in numerous studies, reinforcing its status as a reliable choice for a range of construction needs. Experts in the field recognize that continuing advancements in material science offer solutions that can greatly extend the lifespan and usefulness of construction materials. With industry-recognized certifications and a strong track record in diverse applications worldwide, the authority of HPMC mortar is well cemented in both practical and theoretical realms. In conclusion, the practical experience and extensive expertise surrounding HPMC mortar attribute to its growing popularity in the construction industry. Its ability to improve workability, enhance durability, ensure proper adhesion, and support sustainable practices makes it an authoritative and trusted component of modern construction methodologies. As building innovations continue to evolve, HPMC mortar stands out as a pioneer in redefining how we think about building materials, ensuring structures are not only built to last but are also economically and environmentally sound.

Next:

Latest news

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025