Understanding HPMC in Building Coating Adhesives

Hydroxypropyl Methylcellulose (HPMC) is a non-ionic, water-soluble polymer derived from cellulose. It has become an integral component in the formulation of building coating adhesives due to its remarkable properties that enhance the overall performance of adhesives in construction applications. This article will explore the characteristics, benefits, and applications of HPMC in building coating adhesives.

Properties of HPMC

HPMC exhibits unique properties that make it suitable for use in building coatings. Firstly, it has excellent film-forming capabilities, allowing it to create a smooth and even coating when mixed with adhesives. This property is critical when achieving a uniform surface finish on walls and surfaces.

Secondly, HPMC is known for its high water retention ability. This characteristic is essential in preventing rapid drying during the application process, which can lead to cracking and poor adhesion. With sufficient water retention, HPMC allows for a longer working time, facilitating better application and manipulation of the adhesive.

Additionally, HPMC provides enhanced viscosity control. The viscosity can be adjusted according to the specific requirements of the adhesive formulation, enabling manufacturers to tailor the product for various applications and conditions. The ability to control viscosity is crucial when working with sprayable or brushable adhesives, ensuring optimal performance.

Benefits of HPMC in Building Coating Adhesives

1. Improved Adhesion HPMC significantly enhances the adhesion properties of building coatings. By incorporating HPMC into the adhesive formulation, the bond between the coating and the substrate becomes stronger and more resilient, reducing the likelihood of delamination over time.

2. Workability The incorporation of HPMC results in improved workability of the adhesive. It enables better spread and application without the risk of sagging or dripping, thus ensuring an even layer is applied to surfaces.

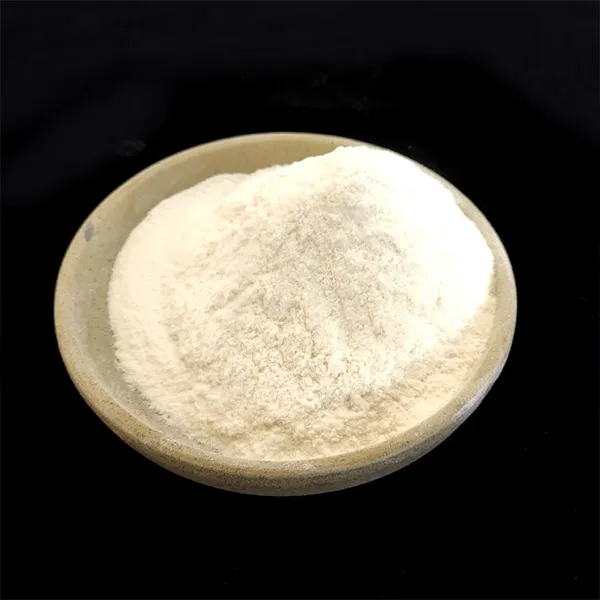

building coating adhesive hpmc

3. Thickening Agent HPMC acts as an effective thickening agent. This is particularly beneficial in construction applications, where adhesives need to maintain their consistency without settling. This thickening property ensures that the adhesive remains easy to apply, even under varying temperature and humidity conditions.

4. Resistant to Environmental Factors Coatings formulated with HPMC exhibit increased resistance to environmental factors such as moisture, temperature fluctuations, and fungal growth. This durability extends the lifespan of the coating, making it suitable for both interior and exterior applications.

5. Eco-friendly HPMC is derived from natural plant cellulose, making it a more environmentally friendly option compared to synthetic additives. Its non-toxic nature aligns well with the growing demand for sustainable construction materials, making it a desirable choice in modern building practices.

Applications in Construction

HPMC is widely used in various building coating applications, including tiles, painting, and plasters. In tile adhesives, HPMC enhances adhesion and provides flexibility, which is crucial in minimizing the effects of thermal expansion and contraction. In paint formulations, it helps achieve the desired viscosity and improves the overall application properties.

Moreover, HPMC is essential in gypsum plasters and renders, where it prevents crack formation by retaining moisture for a longer duration during curing. This preventative strategy is vital for ensuring the longevity and quality of the finished surface.

Conclusion

In conclusion, Hydroxypropyl Methylcellulose (HPMC) serves as a multifaceted additive in building coating adhesives, offering properties that significantly enhance their performance. Its ability to improve adhesion, workability, and environmental resistance makes HPMC an indispensable component in the construction industry. As the demand for eco-friendly and effective building materials continues to rise, the role of HPMC in adhesive formulations will likely expand, benefiting both manufacturers and end-users. With its blend of performance and sustainability, HPMC stands as a crucial ingredient in modern construction technology.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025