The Importance of HPMC in Building Coatings and Adhesives

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether that plays a crucial role in the formulation of building coatings and adhesives. As the construction industry continues to evolve, the demand for high-performance materials has increased, making HPMC an essential ingredient in modern building applications. This article explores the significance of HPMC in building coatings and adhesives, its benefits, and the future potential in construction.

What is HPMC?

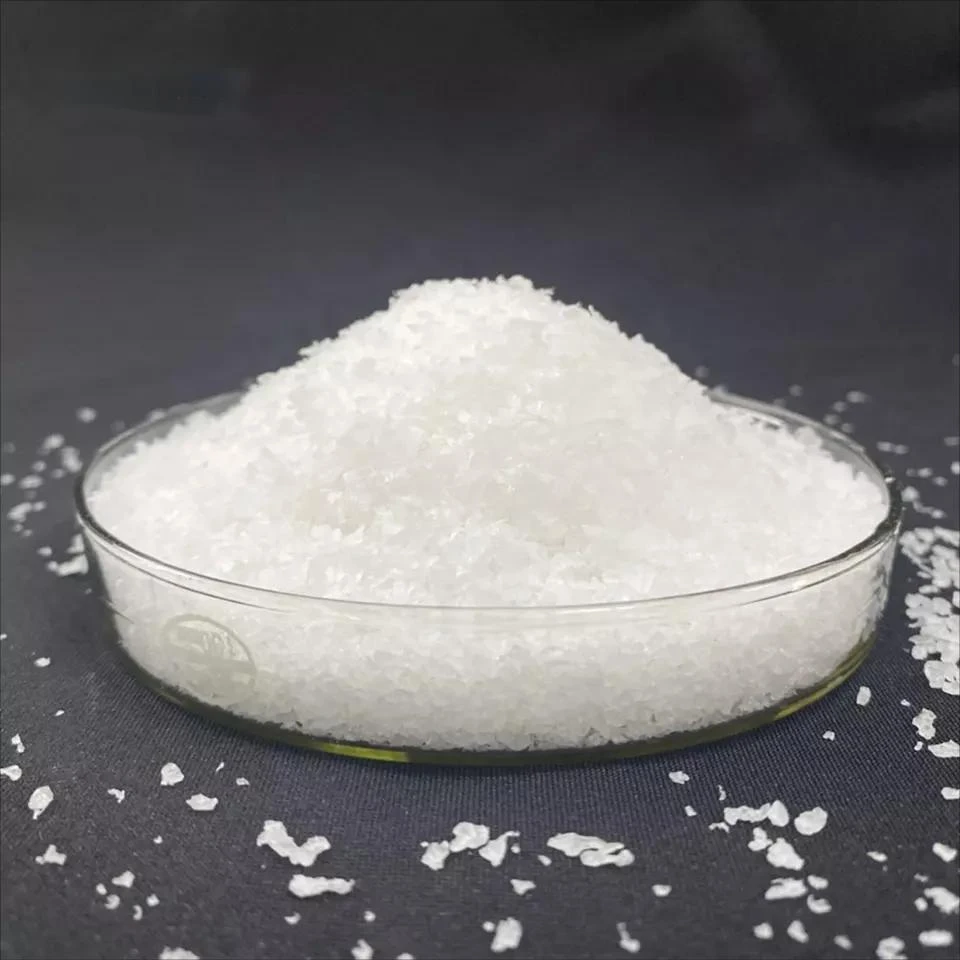

HPMC is a non-ionic cellulose ether derived from natural cellulose. It is produced through the chemical modification of cellulose, which enhances its properties and functionality. HPMC is known for its ability to form a gel when mixed with water, making it an excellent thickening agent. This characteristic, along with its water-retaining abilities, makes HPMC an indispensable component in various construction materials.

Benefits of HPMC in Building Coatings

1. Enhanced Workability HPMC improves the workability of construction materials such as paints and plasters. By providing a smooth and creamy texture, it allows for easier application and better spreading, ensuring a more uniform coverage over surfaces.

2. Water Retention One of the most significant advantages of HPMC is its water-retaining capacity. In building coatings, this property prevents the premature drying of materials, allowing for longer open times and facilitating proper adhesion. This is crucial in environments with varying humidity and temperature levels.

3. Improved Adhesion HPMC improves the bonding properties of coatings and adhesives. This ensures that the coatings adhere well to surfaces, reducing the risk of peeling, cracking, or flaking over time. Strong adhesion is vital for the durability of exterior coatings that withstand harsh weather conditions.

4. Customization of Viscosity HPMC can be formulated to achieve specific viscosity levels, allowing manufacturers to tailor products to meet particular performance requirements. This flexibility makes it suitable for a wide range of applications, from thick plasters to thin paints.

5. Environmental Friendliness As a natural and non-toxic compound, HPMC aligns with the growing trend towards sustainable construction materials. Its biodegradability and low emission of volatile organic compounds (VOCs) make it a suitable choice for environmentally conscious builders and contractors.

building coating adhesive hpmc

HPMC in Adhesives

In adhesive formulations, HPMC serves multiple functions that enhance the performance of the final product.

1. Thickening Agent HPMC acts as a thickener in adhesives, which helps maintain consistency and spreadability. This is particularly important in tile adhesives, where it ensures that the adhesive does not sag or slump after application.

2. Open Time Extension When used in adhesives, HPMC helps extend the open time, allowing users more flexibility during application. This is especially advantageous in situations where precise positioning is required before the adhesive sets.

3. Resistance to Water and Heat HPMC-enhanced adhesives exhibit improved resistance to heat and moisture, making them ideal for both indoor and outdoor applications. This is critical for adhesives used in tile installation, as they need to withstand the rigors of different environments.

Future Potential

As the construction industry moves towards advanced and eco-friendly materials, the role of HPMC is likely to expand. Research and development in HPMC and its derivatives are ongoing, focusing on enhancing its properties and discovering new applications. The continuous push for sustainable building practices will further solidify the position of HPMC in the market.

Moreover, with the rise of smart construction materials, there is a growing interest in incorporating HPMC into new formulations that respond to environmental changes, enhance energy efficiency, and promote overall sustainability in building practices.

Conclusion

HPMC is a cornerstone in the formulation of building coatings and adhesives. Its unique properties, such as enhanced workability, water retention, and improved adhesion, make it an essential additive in achieving high-performance construction materials. As the industry evolves, the potential for HPMC continues to grow, positioning it as a vital ingredient for the future of sustainable construction. The combination of innovation and eco-friendliness surrounding HPMC will undoubtedly lead to better, more efficient building materials, paving the way for advanced construction practices.

-

A Comprehensive Guide to Methyl Ethyl Hydroxyethyl Cellulose: Applications and Industry InsightsNewsNov.24,2025

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025