High-Quality Cellulose Ether HPMC and Its Applications

Cellulose ethers play a critical role in various industries due to their versatile properties and applications. Among them, Hydroxypropyl Methylcellulose (HPMC) stands out as a high-quality cellulose ether that is widely utilized in pharmaceuticals, construction, food, and cosmetics. HPMC is derived from natural cellulose, which is modified to enhance its solubility, thickening ability, and film-forming properties, making it an essential ingredient in many formulations.

What is HPMC?

HPMC is a non-ionic, water-soluble cellulose ether. It is synthesized by the partial substitution of hydroxyl groups in cellulose with hydroxypropyl and methoxy groups. This modification results in a polymer that can dissolve in both cold and hot water, forming a viscous and stable colloidal solution. The degree of substitution and the molecular weight of HPMC can be tailored, allowing for a range of products that exhibit varying viscosities, gel strengths, and release profiles.

Key Properties of HPMC

1. Thickening and Stabilizing Agent HPMC is widely used as a thickener in creams, gels, and sauces due to its ability to increase viscosity without significantly altering the taste or appearance of food products.

2. Controlled Release Agent In pharmaceuticals, HPMC is utilized in matrix tablets and controlled-release formulations. Its properties allow for a slow and controlled release of active ingredients, improving the efficacy and reducing side effects.

3. Film Forming The film-forming capability of HPMC makes it an ideal component in coatings for tablets, providing a protective layer while also facilitating the release of the drug.

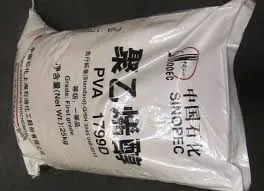

cellulose ether high quality hpmc chemical

Applications of HPMC

1. Pharmaceuticals HPMC is commonly used in the production of tablets, capsules, and other dosage forms. Its ability to control drug release makes it a valuable ingredient in various therapeutic areas, including pain management and chronic diseases.

2. Food Industry In food formulations, HPMC serves as a thickener, emulsifier, and stabilizer, commonly found in sauces, salad dressings, and gluten-free products. It improves texture and extends shelf life without compromising quality.

3. Construction The construction industry benefits from HPMC's ability to enhance the properties of plaster, mortar, and tile adhesives. It ensures better adhesion and workability, essential for high-quality construction applications.

4. Cosmetics and Personal Care HPMC is used in cosmetic formulations as a thickener and stabilizer in creams, lotions, and gels, providing a smooth texture and effective performance.

Conclusion

High-quality cellulose ethers, particularly Hydroxypropyl Methylcellulose, are indispensable in a variety of sectors. Its unique properties make it a versatile ingredient that improves the performance of products across industries. As demand for more effective and functional products rises, the importance of HPMC is likely to grow, solidifying its place as a key player in innovation and quality across different fields. The continued development of cellulose ether technologies promises to expand the possibilities and applications of HPMC, making it a valuable asset in both current and future formulations.