Jan . 30, 2025 01:06

Back to list

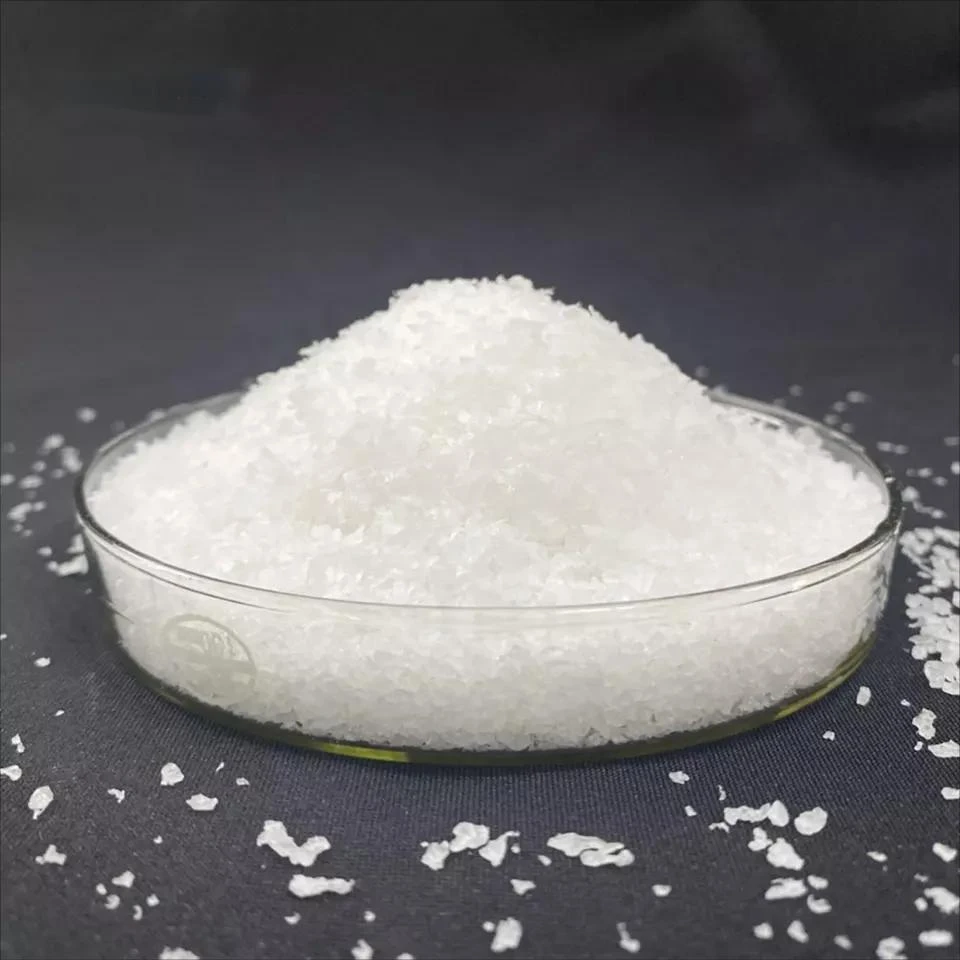

cellulose for paints

Cellulose in paints has become a game-changer for the coatings industry, providing not only ecological benefits but also enhancing performance characteristics that meet modern-day demands. This biodegradable and renewable material is gaining attention for its versatility and its potential to redefine sustainability and efficacy in paint products.

Moreover, the use of cellulose in paint formulations provides excellent biostability, resisting biological degradation which traditionally affects the durability of organic materials. This attribute is instrumental for paints used in environments prone to high humidity and temperature variations, such as kitchens and bathrooms. Cellulose's inherent stability contributes to preserving the integrity and longevity of the paint, thereby extending the lifespan of the investment in renovations or constructions. Industry experts consistently highlight the role of cellulose in improving paint adhesiveness. This improvement is crucial in artistic applications and mural projects where detail and longevity are critical. Enhanced adhesion reduces peeling and flaking, which are common problems in less durable paint blends. The confidence in cellulose as a bonding agent in paints is growing among painters and artists who require reliability and vibrant results over time. The enhanced environmental profile of cellulose paints also promotes healthier indoor air quality. As paints dry, they traditionally release volatile organic compounds (VOCs) that contribute to indoor pollution and health risks. Cellulose-based paints, however, tend to have lower VOC emissions due to their organic composition. This benefits not only the environment but also supports the well-being of inhabitants, making cellulose paint an appealing option for indoor use where air quality is a concern. In conclusion, cellulose for paints represents a significant advancement in the coatings industry, combining eco-friendly attributes with superior functional benefits. Its impact on viscosity, stability, adhesion, and overall sustainability fortifies its position as a critical modern material in paint technology. As the industry evolves towards more responsible production practices, embracing cellulose-based additives seems not just prudent but essential for achieving both performance excellence and environmental stewardship.

Moreover, the use of cellulose in paint formulations provides excellent biostability, resisting biological degradation which traditionally affects the durability of organic materials. This attribute is instrumental for paints used in environments prone to high humidity and temperature variations, such as kitchens and bathrooms. Cellulose's inherent stability contributes to preserving the integrity and longevity of the paint, thereby extending the lifespan of the investment in renovations or constructions. Industry experts consistently highlight the role of cellulose in improving paint adhesiveness. This improvement is crucial in artistic applications and mural projects where detail and longevity are critical. Enhanced adhesion reduces peeling and flaking, which are common problems in less durable paint blends. The confidence in cellulose as a bonding agent in paints is growing among painters and artists who require reliability and vibrant results over time. The enhanced environmental profile of cellulose paints also promotes healthier indoor air quality. As paints dry, they traditionally release volatile organic compounds (VOCs) that contribute to indoor pollution and health risks. Cellulose-based paints, however, tend to have lower VOC emissions due to their organic composition. This benefits not only the environment but also supports the well-being of inhabitants, making cellulose paint an appealing option for indoor use where air quality is a concern. In conclusion, cellulose for paints represents a significant advancement in the coatings industry, combining eco-friendly attributes with superior functional benefits. Its impact on viscosity, stability, adhesion, and overall sustainability fortifies its position as a critical modern material in paint technology. As the industry evolves towards more responsible production practices, embracing cellulose-based additives seems not just prudent but essential for achieving both performance excellence and environmental stewardship.

Next:

Latest news

-

A Comprehensive Guide to Methyl Ethyl Hydroxyethyl Cellulose: Applications and Industry InsightsNewsNov.24,2025

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025