Jan . 30, 2025 01:50

Back to list

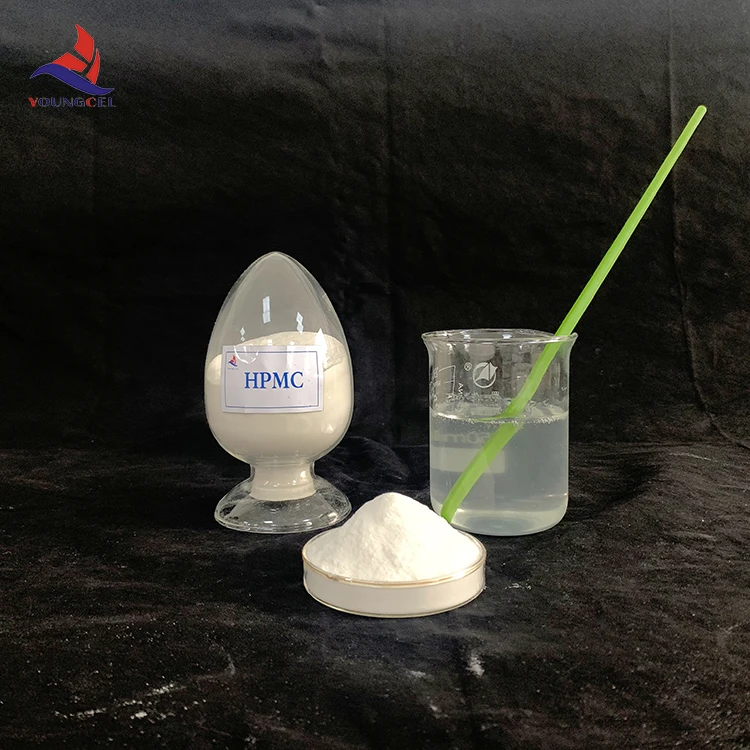

cellulose hpmc for paint

Cellulose ethers, particularly Hydroxypropyl Methylcellulose (HPMC), have revolutionized the paint industry, offering multifaceted benefits that enhance product performance and application methods. Understanding HPMC's role in paint formulation not only requires specialized knowledge but also demands a recognition of the material’s impact on both the manufacturing process and the end-user experience.

In terms of drying characteristics, HPMC’s water retention capabilities play a crucial role. By moderating the evaporation rate of water from the paint, HPMC ensures a controlled drying process, which enhances film formation and minimizes the likelihood of defects such as cracking or chalking. This expertise supports the creation of durable and resilient coatings, further establishing trust in HPMC-formulated paints for both aesthetic and protective purposes. From a practical experience perspective, paint formulators find that using HPMC offers a high degree of flexibility. Adjustments can be made to formulations to meet specific performance criteria without compromising quality. This adaptability is particularly beneficial in addressing diverse environmental conditions and substrate types that might challenge lesser-quality paints. Formulators familiar with HPMC recognize its authoritative role in balancing these variables, ensuring optimal outcomes in various applications. Finally, HPMC contributes to the environmental responsibility of paint products. Being derived from renewable sources and biodegradable in nature, it aligns with the growing consumer demand for sustainable solutions. Industry experts advocate for the integration of HPMC in eco-friendly paints, reinforcing the paint industry's commitment to reducing its environmental footprint. In conclusion, Hydroxypropyl Methylcellulose (HPMC) is not merely an additive but a cornerstone in the development of modern paints that meet today's stringent quality and environmental standards. Its application enhances the physical properties of paints, ensures greater efficiency in use, and provides an authoritative solution to industry challenges. As a reliable, versatile, and sustainable choice, HPMC commands a respected position among paint formulators, underpinned by its proven performance and enduring credibility.

In terms of drying characteristics, HPMC’s water retention capabilities play a crucial role. By moderating the evaporation rate of water from the paint, HPMC ensures a controlled drying process, which enhances film formation and minimizes the likelihood of defects such as cracking or chalking. This expertise supports the creation of durable and resilient coatings, further establishing trust in HPMC-formulated paints for both aesthetic and protective purposes. From a practical experience perspective, paint formulators find that using HPMC offers a high degree of flexibility. Adjustments can be made to formulations to meet specific performance criteria without compromising quality. This adaptability is particularly beneficial in addressing diverse environmental conditions and substrate types that might challenge lesser-quality paints. Formulators familiar with HPMC recognize its authoritative role in balancing these variables, ensuring optimal outcomes in various applications. Finally, HPMC contributes to the environmental responsibility of paint products. Being derived from renewable sources and biodegradable in nature, it aligns with the growing consumer demand for sustainable solutions. Industry experts advocate for the integration of HPMC in eco-friendly paints, reinforcing the paint industry's commitment to reducing its environmental footprint. In conclusion, Hydroxypropyl Methylcellulose (HPMC) is not merely an additive but a cornerstone in the development of modern paints that meet today's stringent quality and environmental standards. Its application enhances the physical properties of paints, ensures greater efficiency in use, and provides an authoritative solution to industry challenges. As a reliable, versatile, and sustainable choice, HPMC commands a respected position among paint formulators, underpinned by its proven performance and enduring credibility.

Next:

Latest news

-

A Comprehensive Guide to Methyl Ethyl Hydroxyethyl Cellulose: Applications and Industry InsightsNewsNov.24,2025

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025