The Role of Cellulose and HPMC in Modern Applications

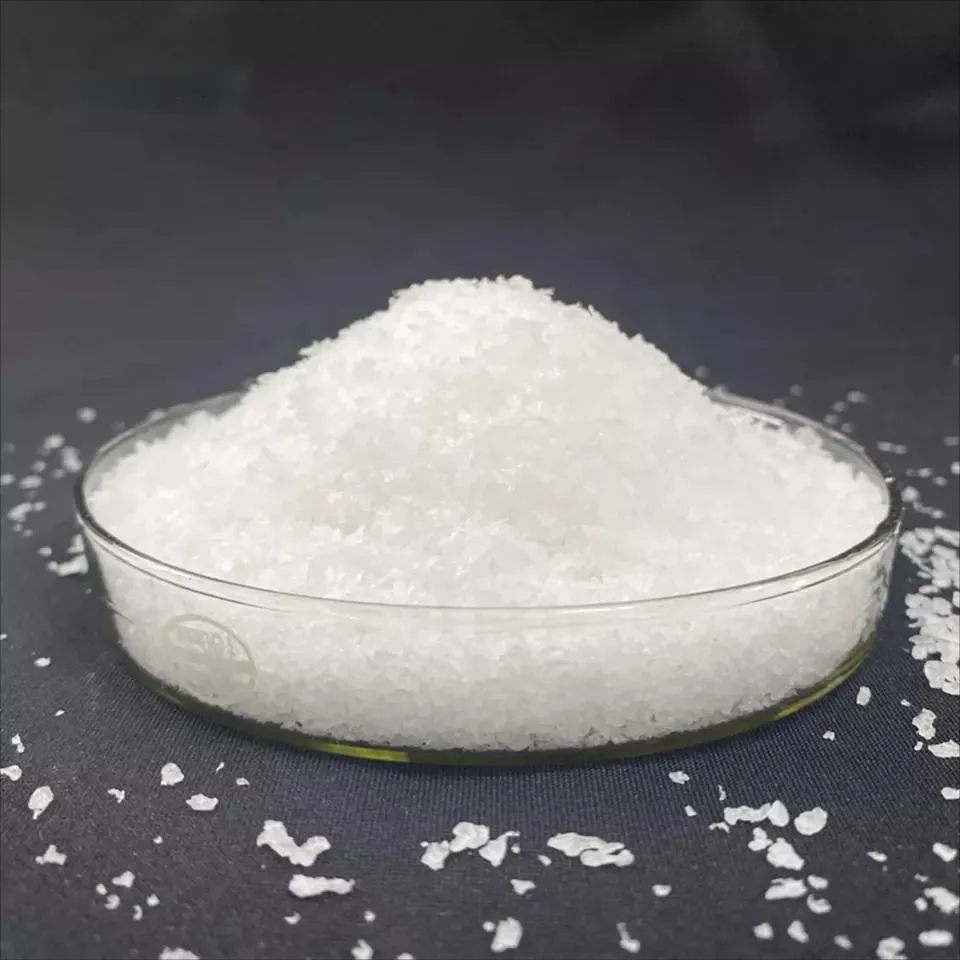

In recent years, cellulose derivatives such as Hydroxypropyl Methylcellulose (HPMC) have captivated widespread attention for their versatile applications across various industries. As a non-ionic, water-soluble polymer derived from natural cellulose, HPMC has become an essential ingredient in pharmaceuticals, food products, cosmetics, and construction materials. This article delves into the significance, properties, and applications of cellulose and HPMC, shedding light on why they are pivotal in contemporary material science.

The Role of Cellulose and HPMC in Modern Applications

In the pharmaceutical industry, HPMC is widely utilized as a binder, thickener, and stabilizing agent. It is particularly important for the formulation of controlled-release drugs, where it helps to regulate the release of active ingredients in the body. By modifying the viscosity of solutions, HPMC also helps to achieve the desired texture in topical formulations, ensuring they adhere well to the skin while providing effective drug delivery. Moreover, HPMC is employed as an excipient in tablets and capsules, contributing to the uniform distribution of active components, which is critical in ensuring consistent therapeutic effects.

cellulos hpmc

The food industry also benefits significantly from HPMC. Its ability to form gels and act as a thickening agent makes it suitable for various food products, including sauces, dressings, and confectionery. HPMC contributes to the texture and mouthfeel of foods, which enhances the overall consumer experience. As a non-caloric thickening agent, it is often favored in low-fat and diet products, providing a desirable viscosity without adding unnecessary calories. Additionally, it aids in moisture retention, which can extend the shelf life of food products, emphasizing its role in food preservation.

In the realm of cosmetics and personal care, HPMC’s emulsifying and stabilizing properties are invaluable. It is found in many formulations, including creams, lotions, shampoos, and gels, where it adds viscosity and enhances the stability of emulsions. HPMC is also utilized in the formulation of hair styling products, offering hold and structure without the stickiness or residue associated with other thickeners. The lightweight feel and ability to enhance the sensory attributes of personal care products make HPMC a popular choice among formulators.

Furthermore, the construction industry has started to leverage the benefits of HPMC in various applications. In cement and mortar products, HPMC improves workability, water retention, and adhesion properties, which are essential for achieving durable and high-performance building materials. Its role in improving the performance of tile adhesives and joint compounds underscores the importance of cellulose derivatives in modern construction practices.

In conclusion, cellulose and its derivative, Hydroxypropyl Methylcellulose (HPMC), have emerged as crucial components across a multitude of industries. Their unique properties—such as water solubility, film-forming ability, and thickening characteristics—enable a broad spectrum of applications that enhance product performance and consumer satisfaction. As industries continue to innovate and seek sustainable solutions, the significance of cellulose and HPMC is poised to grow even further. The versatility of these materials not only underscores their historical importance but also highlights their potential for future advancements in technology and product development.

-

The Application and Significance of Construction RdpNewsMay.19,2025

-

Industrial Grade HpmcNewsMay.19,2025

-

Building Coating Adhesive Building Coating Adhesive HpmcNewsMay.19,2025

-

Application Of Hpmc For Detergent For Detergent In DetergentsNewsMay.19,2025

-

Application Of Hpmc Cellulose In Cement-Based MaterialsNewsMay.19,2025

-

Application Of High Quality Hpmc For Construction In The Field Of ConstructionNewsMay.19,2025