The Role of Cement Additives in Modern Construction

Cement is a fundamental material in the construction industry, serving as a binding agent that holds various building materials together. Over the years, advancements in technology and material science have led to the development of various cement additives that enhance the properties of cement, improve workability, and optimize the overall performance of concrete. Understanding the role and importance of these additives is essential for modern construction practices.

Cement additives, also known as admixtures, are substances added to cement before or during mixing to modify its properties. They can be broadly categorized into three main types chemical additives, mineral additives, and specialty additives. Each type serves a unique purpose and can significantly influence the final product’s strength, durability, and appearance.

Chemical Additives

Chemical additives are the most commonly used type of admixture in construction. They can be further divided into several subcategories, including plasticizers, superplasticizers, accelerators, retarders, and air-entraining agents.

Plasticizers and superplasticizers, for example, improve the workability of fresh concrete without compromising its strength. This property is particularly beneficial in complex or intricate designs where the ease of placement is crucial. Accelerators can speed up the setting time of concrete, making it ideal for projects that require rapid construction or in cold weather conditions. On the other hand, retarders delay the setting time, allowing for extended workability in hot weather or large-scale pours. Lastly, air-entraining agents introduce tiny air bubbles into the concrete mix, enhancing its resistance to freeze-thaw cycles, which is essential in colder climates.

Mineral Additives

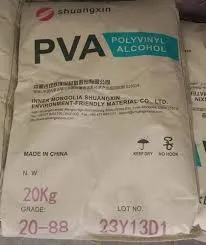

cement additives

Mineral additives, such as fly ash, slag cement, and silica fume, are used to improve the mechanical properties and durability of concrete. These materials are by-products of industrial processes and contribute to sustainable construction practices by reducing the environmental impact of cement production.

For instance, fly ash, a by-product of coal combustion, can replace a portion of Portland cement in concrete. It not only enhances strength and durability but also improves the workability of the mix. Slag cement, derived from steel production, possesses pozzolanic properties that increase the concrete’s resistance to chemical attacks, while silica fume, a by-product of silicon metal production, significantly improves the concrete's compressive strength and reduces permeability, ensuring a longer lifespan for structures.

Specialty Additives

Specialty additives are designed for specific purposes, addressing unique challenges in construction projects. These may include waterproofing agents that prevent water infiltration, corrosion inhibitors that protect reinforcing steel, and shrinkage-reducing agents that minimize cracking. The selection of the right specialty additive can significantly influence the long-term performance and reliability of concrete structures.

Conclusion

The incorporation of cement additives is a crucial aspect of modern construction practices. By utilizing these materials, engineers and architects can design concrete that meets the specific requirements of various projects, from residential buildings to large infrastructures. As sustainability becomes increasingly important in construction, the use of mineral additives emphasizes the industry's shift towards environmentally friendly practices.

Overall, cement additives play an essential role in enhancing the performance, durability, and sustainability of concrete. As technology continues to advance, the development of new additives will likely expand the possibilities for construction, leading to better, more resilient structures that can withstand the test of time and environmental challenges. Embracing these innovations is key to building a safer and more sustainable future in the construction industry.