The Importance of Chemical Composition in Tile Bonding

Tile bonding plays a crucial role in both the aesthetics and functionality of various surfaces in homes and commercial spaces. Whether for floors, walls, or backsplashes, the quality of tile adhesion is paramount to ensuring durability, resistance to moisture, and overall longevity of tiled surfaces. At the heart of effective tile bonding is an understanding of the chemical composition of adhesives and bonding agents used in the tile installation process.

Understanding Tile Adhesives

Tile adhesives are specialized compounds designed to create a strong bond between tiles and various substrates, like concrete, cement backer board, or wood. These adhesives can be organic or inorganic, with formulations that cater to different types of tiles, such as ceramic, porcelain, or natural stone, and specific environmental conditions.

1. Organic Adhesives These include mastic and thin-set mortars made from polymer compounds. They are often water-resistant and provide good adhesion for wall tiles and light-duty flooring applications. However, they are not suitable for wet areas like showers or external installations.

2. Inorganic Adhesives These are typically cement-based, providing superior strength and durability, making them ideal for heavier tiles and high-moisture applications. They often include additives to enhance workability, improve bond strength, and prevent cracking.

Chemical Composition of Tile Adhesives

The effectiveness of tile adhesives largely depends on their chemical composition, which can significantly impact performance characteristics such as bonding strength, flexibility, and moisture resistance. Key components typically found in tile adhesives include

- Cement Most tile adhesives are fundamentally based on Portland cement, which acts as a binder. The chemistry of cement hydration contributes to the adhesive's strength as it cures and hardens.

- Polymers Many modern adhesives incorporate polymer additives, such as latex, to improve flexibility and bonding strength. These polymers enhance the adhesive’s ability to withstand movement and thermal expansion, reducing the risk of cracks.

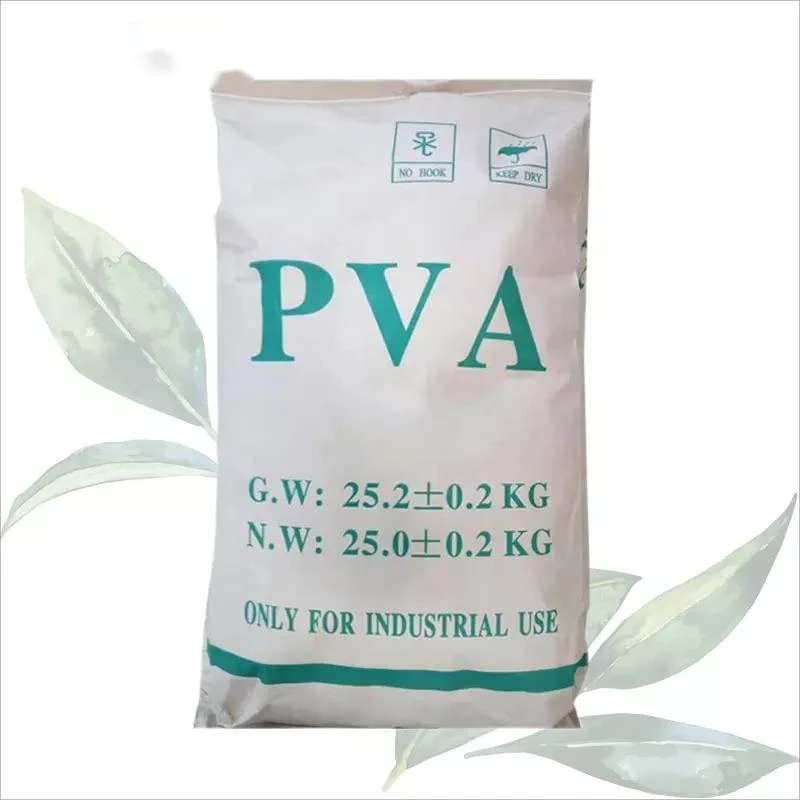

chemical for tile bond

- Aggregates Fine aggregates, such as sand, are often included to improve the workability and application of the adhesive. The right grading of aggregates is crucial to ensuring the adhesive spreads evenly and achieves good contact with both the tile and substrate.

- Additives Various additives are formulated into tile adhesives to cater to specific needs. For instance, water-retention agents enhance the adhesive's performance in hot conditions by preventing rapid drying, while anti-slip additives improve safety during tile installation.

Factors That Influence Tile Bonding Performance

Several environmental and material factors can influence the performance of tile adhesives

1. Surface Preparation The substrate must be clean, dry, and free from contaminants for optimal adhesion. Uneven surfaces can also compromise the bond, leading to tile failure.

2. Temperature and Humidity Ambient conditions during installation can affect the curing process of adhesives. High humidity may slow down curing, while extreme heat can lead to rapid evaporation of water in the adhesive, impacting its performance.

3. Tile Material Different tile materials require different adhesive formulations. For example, natural stone tiles may need specific adhesives to prevent discoloration or damage.

4. Moisture Exposure Areas prone to water exposure, such as bathrooms or kitchens, necessitate the use of water-resistant or waterproof adhesives to prevent degradation over time.

Conclusion

The right choice of chemical composition in tile adhesives is key to achieving strong and long-lasting tile bonds. Understanding the nuances of different adhesive types, their individual components, and the influencing factors can lead to successful and durable tiling projects. As innovations continue to develop in the field of tile adhesives, professionals and DIY enthusiasts alike must stay informed to select the best products suited for their specific needs. Ultimately, a solid bond not only enhances the aesthetic appeal of tiled surfaces but also contributes significantly to the structural integrity and lifespan of installations.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025