Jan . 19, 2025 04:12

Back to list

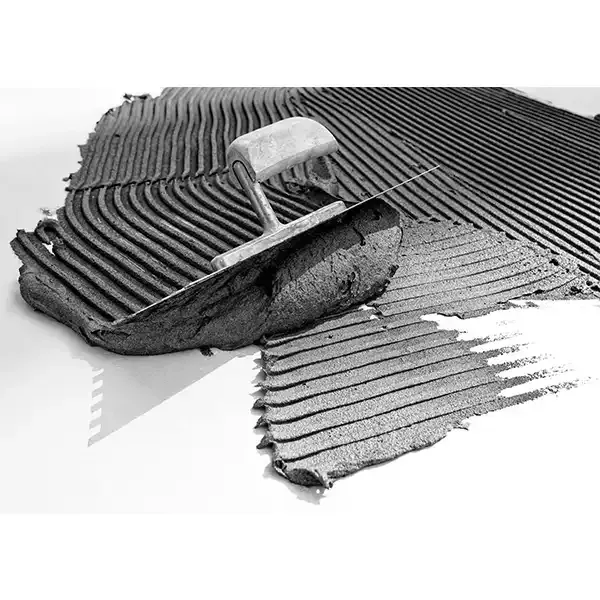

High quality chemical additive MHEC ceramic tile adhesive cellulose Powder 9032-42-2

Concrete additives have revolutionized the construction industry, offering innovations that enhance the strength, durability, and overall performance of concrete. These additives, often referred to as admixtures, are natural or manufactured chemicals that are added to the concrete mix either before or during the mixing process. The rise of these materials showcases not only the evolution of construction technologies but also the increasing demands for efficiency and sustainability within the field.

Corrosion is a perpetual concern in environments where surfaces might be exposed to chemicals or saltwater. Experienced specialists highlight that corrosion-inhibiting additives are particularly beneficial for structures like bridges or parking garages, which are consistently at risk. These inhibitors form a protective layer around steel rebar, preventing rust and extending the lifespan of the concrete structure. Addressing shrinkage and cracking has been another focal point for experts utilizing concrete additives. Air-entraining agents have been instrumental in improving the freeze-thaw durability of concrete. By introducing billions of tiny air bubbles into the mix, these agents relieve internal pressure on the concrete during freeze-thaw cycles, mitigating the risk of cracking and surface degradation. The role of advanced fiber additives in concrete cannot be understated. Polypropylene and steel fibers can increase tensile strength, ductility, and impact resistance, offering concrete the ability to withstand stress and deformation. This is especially beneficial in projects requiring high-performance concrete, such as tunnels, pavements, and industrial floors that endure heavy traffic and load. Moreover, as the field continues to evolve, nanotechnology is emerging as the next frontier. Nanoscale additives, such as nanoclays and nanosilica, enhance concrete properties at the molecular level, improving durability, reducing porosity, and enabling self-healing capabilities. Specialists speculate that, with continued research, these additives may redefine performance standards in the coming years. In sum, concrete additives present a mosaic of opportunities and advancements, grounded in experience, fortified by expertise, and underscored by trust and authority within the construction sector. From improving workability and cure rates to offering sustainable and durable solutions, these admixtures are crucial components in the modern construction toolkit. As the industry pushes forward, the integration of these innovative materials will only continue to expand, paving the way for smarter, more resilient infrastructure across the globe.

Corrosion is a perpetual concern in environments where surfaces might be exposed to chemicals or saltwater. Experienced specialists highlight that corrosion-inhibiting additives are particularly beneficial for structures like bridges or parking garages, which are consistently at risk. These inhibitors form a protective layer around steel rebar, preventing rust and extending the lifespan of the concrete structure. Addressing shrinkage and cracking has been another focal point for experts utilizing concrete additives. Air-entraining agents have been instrumental in improving the freeze-thaw durability of concrete. By introducing billions of tiny air bubbles into the mix, these agents relieve internal pressure on the concrete during freeze-thaw cycles, mitigating the risk of cracking and surface degradation. The role of advanced fiber additives in concrete cannot be understated. Polypropylene and steel fibers can increase tensile strength, ductility, and impact resistance, offering concrete the ability to withstand stress and deformation. This is especially beneficial in projects requiring high-performance concrete, such as tunnels, pavements, and industrial floors that endure heavy traffic and load. Moreover, as the field continues to evolve, nanotechnology is emerging as the next frontier. Nanoscale additives, such as nanoclays and nanosilica, enhance concrete properties at the molecular level, improving durability, reducing porosity, and enabling self-healing capabilities. Specialists speculate that, with continued research, these additives may redefine performance standards in the coming years. In sum, concrete additives present a mosaic of opportunities and advancements, grounded in experience, fortified by expertise, and underscored by trust and authority within the construction sector. From improving workability and cure rates to offering sustainable and durable solutions, these admixtures are crucial components in the modern construction toolkit. As the industry pushes forward, the integration of these innovative materials will only continue to expand, paving the way for smarter, more resilient infrastructure across the globe.

Next:

Latest news

-

A Comprehensive Guide to Methyl Ethyl Hydroxyethyl Cellulose: Applications and Industry InsightsNewsNov.24,2025

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025