The Significance of Cellulose and HPMC in Modern Applications

Cellulose has been a cornerstone of various industries for centuries, serving as a primary structural component of plant cell walls. This biopolymer, consisting of glucose monomers linked by β-1,4-glycosidic bonds, is not only abundant and renewable but also non-toxic, which makes it an environmentally friendly option in various applications. The advancements in cellulose derivatives, notably Hydroxypropyl Methylcellulose (HPMC), have opened up new avenues in pharmaceuticals, food products, and construction.

The Significance of Cellulose and HPMC in Modern Applications

In the pharmaceutical industry, HPMC is widely utilized as a binder and controlled-release agent in tablet formulations. Its gel-forming ability in aqueous solutions allows for the gradual release of active pharmaceutical ingredients (APIs), leading to improved bioavailability and patient compliance. Moreover, HPMC serves as a coating agent that can provide taste masking and protect sensitive drugs from environmental factors, thereby extending shelf life. The growing demand for modified-release medications and the increasing prevalence of chronic diseases are expected to bolster the market for HPMC in pharmaceuticals.

celulose hpmc

In the food industry, HPMC is recognized for its thickening and emulsifying properties, making it a popular choice in various food applications such as sauces, dressings, and baked goods. It acts as a stabilizer that enhances texture and mouthfeel while retaining moisture in baked products. With an increasing trend towards clean-label products, HPMC stands out as a vegan alternative to gelatin and egg whites, making it suitable for a broad range of dietary preferences. As consumers become more health-conscious, the demand for natural and functional ingredients in food formulations is likely to increase, further establishing HPMC's role in this sector.

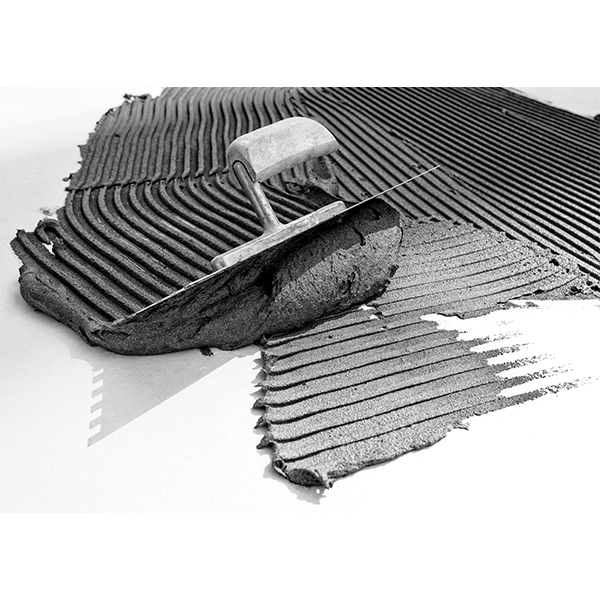

The construction industry also benefits from the properties of HPMC, particularly in cement and plaster formulations. HPMC improves workability, water retention, and adhesion, which are crucial for achieving superior performance in construction materials. Its ability to enhance the spreadability and open time of mortars makes it a valuable additive, especially for tile adhesives and repair mortars. As the construction sector increasingly focuses on sustainability and efficiency, HPMC's role in promoting durable and high-quality building materials is critical.

Furthermore, the development of innovative cellulose derivatives continues to expand the realm of possibilities. Research is being conducted to optimize extraction methods and modify cellulose structures for enhanced performance. The push towards sustainability in various industries has also opened up avenues for biodegradable packaging solutions derived from cellulose, reducing environmental impact while maintaining functionality.

In conclusion, cellulose and its derivative, HPMC, are pivotal components that play crucial roles in multiple industries today. Their unique properties cater to a wide array of applications, from pharmaceuticals and food products to construction materials. With the ongoing innovations and a growing commitment to sustainable practices, the future of cellulose and HPMC in the marketplace looks promising. As industries continue to seek out natural and efficient solutions, the importance of these materials will undoubtedly increase, paving the way for new advancements and applications in the years to come.

-

The Application and Significance of Construction RdpNewsMay.19,2025

-

Industrial Grade HpmcNewsMay.19,2025

-

Building Coating Adhesive Building Coating Adhesive HpmcNewsMay.19,2025

-

Application Of Hpmc For Detergent For Detergent In DetergentsNewsMay.19,2025

-

Application Of Hpmc Cellulose In Cement-Based MaterialsNewsMay.19,2025

-

Application Of High Quality Hpmc For Construction In The Field Of ConstructionNewsMay.19,2025