Jan . 14, 2025 11:52

Back to list

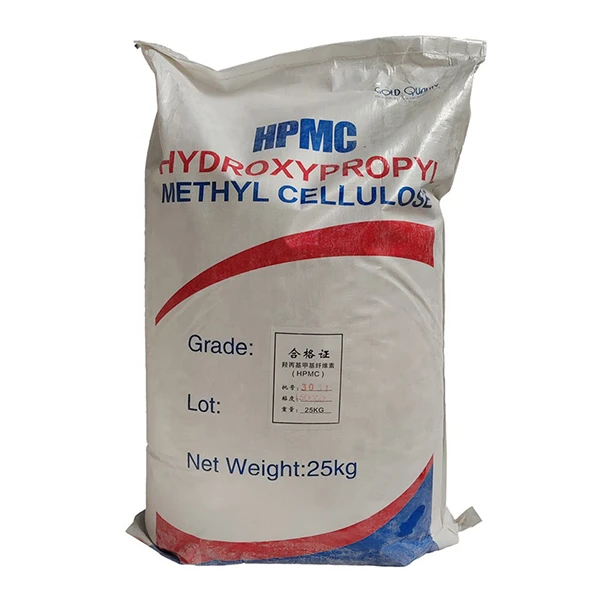

Hot Selling Cellulose For Cement Paint Coating Powder Gypsum Mhec MHPC/MHPC Walocel

Navigating the world of tile bond chemicals can be a game changer for any tiling project. Known for their incredible adhesive properties, tile bond chemicals ensure that tiles, whether ceramic, porcelain, or natural stone, stay in place firmly, enduring wear, tear, and the passage of time. Understanding these versatile substances can significantly bolster the longevity and aesthetic appeal of tiled surfaces.

Authoritative organizations and industry standards play an equally crucial role in setting benchmarks for tile bond chemical performance. Certifications by recognized bodies assure users of the product's adherence to stringent quality and safety standards. This layer of reassurance enhances the trustworthiness of the chemical, making it a reliable choice for architects and contractors alike. When selecting a tile bond chemical, it's also essential to consider the manufacturer's reputation, product reviews, and real-world application testimonies. Brands that consistently deliver excellence and innovation often gain a loyal consumer base, driven by positive outcomes and enduring results. Reading comprehensive reviews and consulting with industry peers can provide invaluable insights, supporting informed decision-making and optimal product choice. Ultimately, the choice of tile bond chemical can have a profound impact on the success and durability of a tiling project. Armed with experience, expertise, trust, and authority, builders and DIY enthusiasts can navigate through the myriad of options to select a product that complements their specific needs, ensuring robust and aesthetically stunning results for years to come.

Authoritative organizations and industry standards play an equally crucial role in setting benchmarks for tile bond chemical performance. Certifications by recognized bodies assure users of the product's adherence to stringent quality and safety standards. This layer of reassurance enhances the trustworthiness of the chemical, making it a reliable choice for architects and contractors alike. When selecting a tile bond chemical, it's also essential to consider the manufacturer's reputation, product reviews, and real-world application testimonies. Brands that consistently deliver excellence and innovation often gain a loyal consumer base, driven by positive outcomes and enduring results. Reading comprehensive reviews and consulting with industry peers can provide invaluable insights, supporting informed decision-making and optimal product choice. Ultimately, the choice of tile bond chemical can have a profound impact on the success and durability of a tiling project. Armed with experience, expertise, trust, and authority, builders and DIY enthusiasts can navigate through the myriad of options to select a product that complements their specific needs, ensuring robust and aesthetically stunning results for years to come.

Latest news

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025