The construction industry constantly seeks innovative materials that enhance structural integrity, durability, and sustainability. One such material that has gained prominence in recent years is HPMC mortar, which stands for Hydroxypropyl Methylcellulose mortar. HPMC is a versatile and high-performance polymer that is particularly valued for its use in various construction applications, including tiling, plastering, and rendering.

HPMC is categorized as a cellulose ether, derived from natural cellulose found in plant cell walls. Its chemical modification allows it to function as an effective thickening agent, stabilizer, and film-forming agent. When integrated into mortar formulations, HPMC significantly improves the performance characteristics of the mixture, leading to enhanced workability, adhesion, and water retention.

.

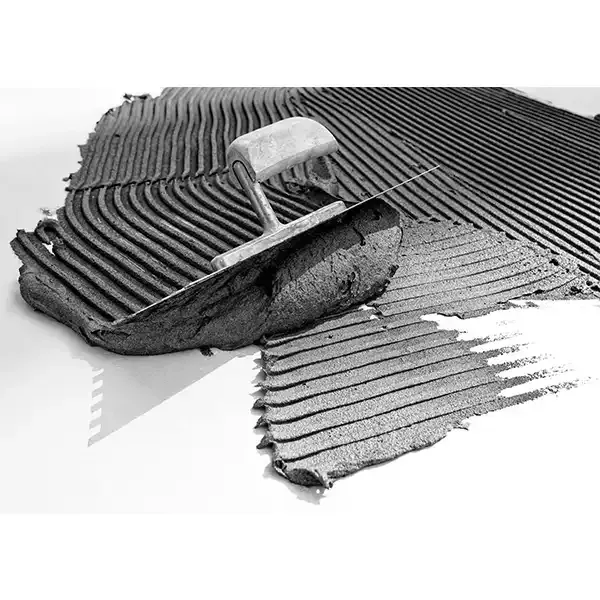

Furthermore, HPMC enhances the adhesion of the mortar to various substrates. This characteristic is particularly important when working with challenging surfaces or in environments where traditional mortars may struggle to bond effectively. Whether it’s bonding tiles to concrete, masonry, or drywall, HPMC mortar ensures a secure grip that contributes to the longevity and stability of the installation.

hpmc mortar

Water retention is another key benefit of HPMC mortar. Traditional mortars can dry out too quickly, especially in hot or dry conditions, which can lead to cracking, reduced strength, and compromised performance. HPMC’s water-retentive properties counteract this issue by maintaining adequate moisture levels within the mortar during the curing process. This results in better hydration of the cement, leading to improved strength and durability.

In addition to its performance benefits, HPMC mortar is also considered an environmentally friendly option. The use of cellulose derivatives like HPMC allows for the production of mortars that require fewer synthetic additives, reducing the overall environmental impact. As the construction industry increasingly emphasizes sustainability, materials like HPMC mortar align well with these goals.

Another noteworthy aspect of HPMC mortar is its versatility. It can be adapted to suit various types of projects, from residential to commercial applications. Whether used as a thick bed mortar for large-format tiles or as a thin-set for intricate designs, HPMC-modified formulations can accommodate a wide range of construction needs.

In conclusion, HPMC mortar represents a significant advancement in construction materials, offering multiple advantages that enhance both the performance of the mortar and the overall efficiency of construction projects. With its improved workability, adhesion, water retention, and eco-friendliness, it is poised to become a staple in modern construction practices. As the industry continues to evolve, the incorporation of innovative materials like HPMC will play a crucial role in shaping the future of building techniques and standards.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025