The Role of HPMC Mortar in Modern Construction

Hydroxypropyl Methylcellulose (HPMC) has become an essential ingredient in modern construction, particularly in the formulation of mortars. This cellulose ether is predominantly used as a thickening agent, binder, and film-forming agent. With the increasing demand for high-performance building materials, HPMC mortar has gained popularity due to its excellent properties that contribute to the durability and efficiency of construction projects.

Composition and Properties of HPMC Mortar

HPMC is derived from cellulose, a natural polymer found in the cell walls of plants. Its modification allows for enhanced solubility and performance in various applications. When incorporated into mortar, HPMC offers several beneficial properties.

Firstly, HPMC significantly improves the workability of the mortar. This facilitates easier application and spreading, allowing construction professionals to achieve a smoother finish. The enhanced workability results from HPMC's ability to retain water, which helps maintain the moisture content of the mortar during application and curing.

Secondly, HPMC mortar exhibits excellent adhesion properties. The presence of HPMC enhances the binding capacity of the mortar to substrates, ensuring that tiles, bricks, or other materials adhere firmly. This is particularly crucial in tile installations, where insufficient adhesion can lead to delamination and ultimately result in structural failure.

Another critical property of HPMC mortar is its water retention capability. HPMC particles can effectively trap water within the mortar matrix, preventing premature drying. This property allows the mortar to cure properly, which is vital for achieving optimal strength. Additionally, improved water retention translates to increased flexibility and reduced cracking, ensuring long-lasting results.

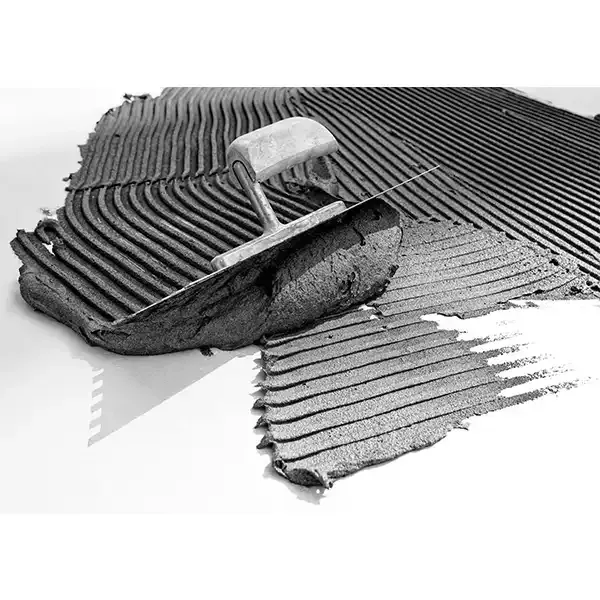

hpmc mortar

Applications in Construction

The applications of HPMC mortar are extensive. In tile and stone installations, its superior adhesion and water retention make it a preferred choice for both interior and exterior projects. It works well in various temperatures and conditions, making it suitable for diverse environments, from hot, arid areas to humid climates.

Moreover, HPMC is commonly used in rendering and masonry mortars. Its excellent workability is advantageous for achieving smooth finishes and intricate designs. The use of HPMC also minimizes the risk of shrinkage cracks during the curing process, a crucial aspect in enhancing the durability of rendered surfaces.

In addition to its performance features, HPMC mortar is environmentally friendly. As a cellulose-based material, it contributes to sustainable construction practices. The incorporation of HPMC into mortar formulations reduces the need for synthetic additives, which can be harmful to the environment. Its biodegradability further underscores its appeal for eco-conscious builders.

Conclusion

In conclusion, the incorporation of Hydroxypropyl Methylcellulose into mortars represents a significant advancement in construction materials. Its properties enhance the workability, adhesion, and durability of mortars, making it an essential component in tile installations, rendering, and masonry works. As the construction industry continues to evolve, the demand for high-performance materials like HPMC mortar is set to increase, contributing to more sustainable and efficient building practices. With ongoing research and development, the future of HPMC in the construction sector looks promising, paving the way for innovative solutions that meet the challenges of modern architecture.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025