Exploring High-Performance Mortar The HPMC Advantage

In the realm of construction and building materials, the demand for high-performance solutions has never been greater. Among these, High-Performance Mortar (HPM) has emerged as a key player, particularly when enhanced with additives like Hydroxypropyl Methylcellulose (HPMC). This article delves into the composition, benefits, applications, and future of HPMC mortar, illuminating why it stands out in modern construction methodologies.

What is HPMC?

Hydroxypropyl Methylcellulose (HPMC) is a cellulose ether widely used as a thickener, binder, and film-forming agent. Its unique properties make it ideal for formulating high-performance mortars. HPMC is soluble in water and can significantly improve the workability, adhesion, and durability of mortars, making it an essential additive in contemporary construction practices.

Composition of HPM Mortar

High-Performance Mortar typically comprises several key components cement, aggregates, water, and additives such as HPMC. The cement serves as the binding agent, while aggregates provide bulk and strength. Water activates the cement, enabling it to bond with aggregates, and additives like HPMC enhance various performance characteristics.

The incorporation of HPMC into mortar formulation contributes to increased viscosity, better water retention, and improved adhesion between the mortar and substrates. This chemical synergy results in a product that can withstand the rigors of construction while ensuring optimal performance during application.

Benefits of HPMC Mortar

1. Enhanced Workability One of the most significant advantages of HPMC is its ability to improve workability. Mortars formulated with HPMC are easier to mix and apply, allowing for smoother application on surfaces, which is crucial for both professional and DIY projects.

2. Improved Adhesion HPMC mortars exhibit excellent adhesion properties, ensuring that tiles, bricks, and other materials stay securely bonded to substrates. This is particularly important in areas subject to moisture or thermal expansion.

3. Water Retention The water-retention properties of HPMC prevent premature drying of the mortar, which is essential for preventing cracks and ensuring the completeness of the curing process. This also enhances durability over time.

4. Resistance to Cracking Mortars that include HPMC are less prone to shrinkage cracks due to their improved flexibility and water retention capabilities. This property is particularly advantageous in climates with significant temperature fluctuations.

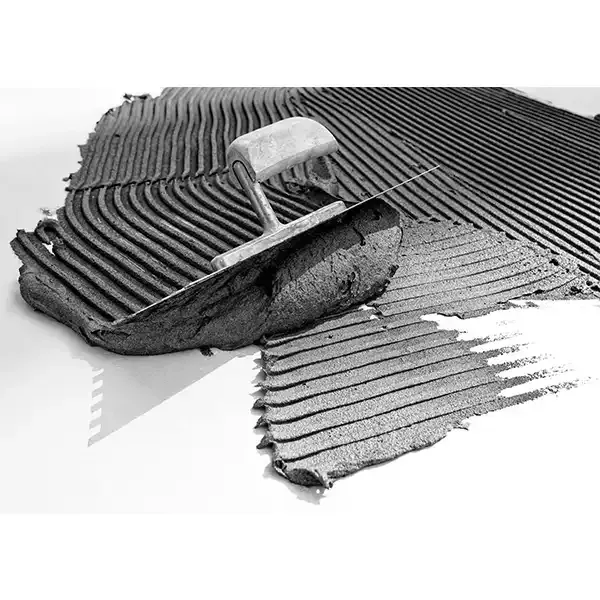

hpmc mortar

5. Versatility in Application HPMC mortars can be used in various applications, including tile bonding, masonry work, and plastering. Their adaptability makes them suitable for both indoor and outdoor applications.

6. Eco-Friendly Many manufacturers are now focusing on producing HPM mortars with lower environmental impacts. The materials and additives used in these mortars often have reduced VOC emissions, aligning with global efforts towards sustainability.

Applications of HPMC Mortar

HPMC mortar is versatile and finds applications across several areas in the construction industry

- Tile Laying Due to its excellent adhesion and flexibility, HPMC mortar is frequently used for laying tiles in bathrooms, kitchens, and outdoor spaces.

- Masonry Work In brick and block laying, the watertight properties of HPMC mortar enhance the overall structural integrity and longevity of the construction.

- Plastering For internal and external walls, HPM mortar provides a smooth finish while ensuring strong adhesion and resistance to environmental factors.

The Future of HPMC Mortar

As the construction industry becomes increasingly focused on sustainability and efficiency, the future of HPMC mortar looks promising. Innovations in formulation and additives aim to enhance the performance further while reducing environmental impacts. Research into bio-based polymers and natural additives may pave the way for new generations of HPMC mortar that are even more ecological and efficient.

Moreover, as urbanization continues to accelerate globally, the demand for high-performance building materials will only grow. HPMC mortar, with its superior properties, is well-positioned to meet these needs, offering robust solutions that ensure the longevity and durability of modern infrastructures.

Conclusion

High-Performance Mortar enhanced with HPMC represents a significant advancement in construction materials, providing robust, durable, and effective solutions for a variety of applications. Its benefits, including improved workability, adhesion, and water retention, position it as a preferred choice for professionals in the industry. As technological advancements continue to unfold, HPMC mortars will undoubtedly play a crucial role in shaping the structures of tomorrow, ensuring they are built to last.