The Role of Industry Thickening in Modern Manufacturing

In the contemporary landscape of industrial manufacturing, the concept of thickness is more than just a measurement; it embodies a realm of significance that influences productivity, efficiency, and product quality across various sectors. From textiles to metals, the principle of thickness—often referred to in technical terms as industry thickening—plays a crucial role in how materials are processed, transformed, and utilized in the manufacturing environment.

Understanding Industrial Thickening

Industrial thickening refers to the methods and technologies employed to increase the thickness or density of a given material without altering its fundamental properties. This concept is pertinent in numerous fields, including paper production, metal fabrication, and the culinary industry, where the thickness of a final product can dramatically affect its functionality, aesthetic appeal, and overall performance.

In the textile industry, for example, thickness can impact not only the durability of a fabric but also its thermal properties and comfort levels. Thicker materials tend to provide better insulation, making them preferable for outerwear designed for cold climates. Such applications require careful consideration of the thickening process, which may include techniques like layering or the integration of loftier fibers that increase the material's bulk without compromising its weight or flexibility.

Techniques for Thickening Materials

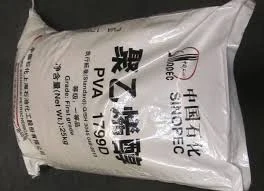

Several techniques are employed to achieve the desired thickness in various industries. One common method is the use of additives or fillers that enhance the density of a base material. In the paint industry, for instance, thickeners are essential for achieving the desired viscosity, which ensures that paint adheres well to surfaces and provides excellent coverage. Such thickeners can be derived from natural sources or synthetically manufactured, each offering different benefits depending on the application.

industri thicken

3D printing is another revolutionary technology impacting industry thickening. With additive manufacturing, thickness can be precisely controlled layer by layer during the creation of a product, allowing for complex designs that were previously impossible. This capability not only optimizes material use but also enables the production of lightweight structures that maintain strength through strategic thickening in critical areas.

Impact on Sustainability and Efficiency

As industries continue to push for sustainability, the role of thickening becomes even more significant. Thicker materials can lead to reduced waste during processing, as they often require less energy to manufacture when optimized efficiently. For example, thicker sheet metal can be cut with less scrap, thereby utilizing more of the raw material and decreasing the overall carbon footprint of the production process.

Moreover, advancements in technology have enabled better predictive analytics that allow manufacturers to determine the optimal thickness needed for specific applications. By using data-driven approaches, industries can minimize material usage while maximizing durability and performance. This not only enhances productivity but also contributes to global sustainability goals.

Challenges and Considerations

However, the pursuit of optimal thickness is not without its challenges. Over-thickening can lead to increased weight, which may affect transportation and handling costs. Additionally, manufacturers must navigate the intricacies of material behavior, as some substances may lose essential properties when excessively thickened. Hence, ongoing research and development into new materials and methods are crucial in addressing these challenges.

In conclusion, industry thickening is a multifaceted concept that significantly impacts modern manufacturing. By understanding and optimizing thickness, industries can enhance product performance, contribute to sustainability efforts, and drive innovation across various sectors. As technology continues to evolve, the potential for new thickening techniques and applications seems limitless, paving the way for a more efficient and environmentally conscious industrial future.

-

The Application and Significance of Construction RdpNewsMay.19,2025

-

Industrial Grade HpmcNewsMay.19,2025

-

Building Coating Adhesive Building Coating Adhesive HpmcNewsMay.19,2025

-

Application Of Hpmc For Detergent For Detergent In DetergentsNewsMay.19,2025

-

Application Of Hpmc Cellulose In Cement-Based MaterialsNewsMay.19,2025

-

Application Of High Quality Hpmc For Construction In The Field Of ConstructionNewsMay.19,2025