Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint is a key solution in the manufacturing industry, specifically within Chemical raw material and chemical product manufacturing industry and Synthetic resin manufacturing. This article explores how Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint Overview

- Benefits & Use Cases of Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint in Synthetic resin manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint from Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.

Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint Overview

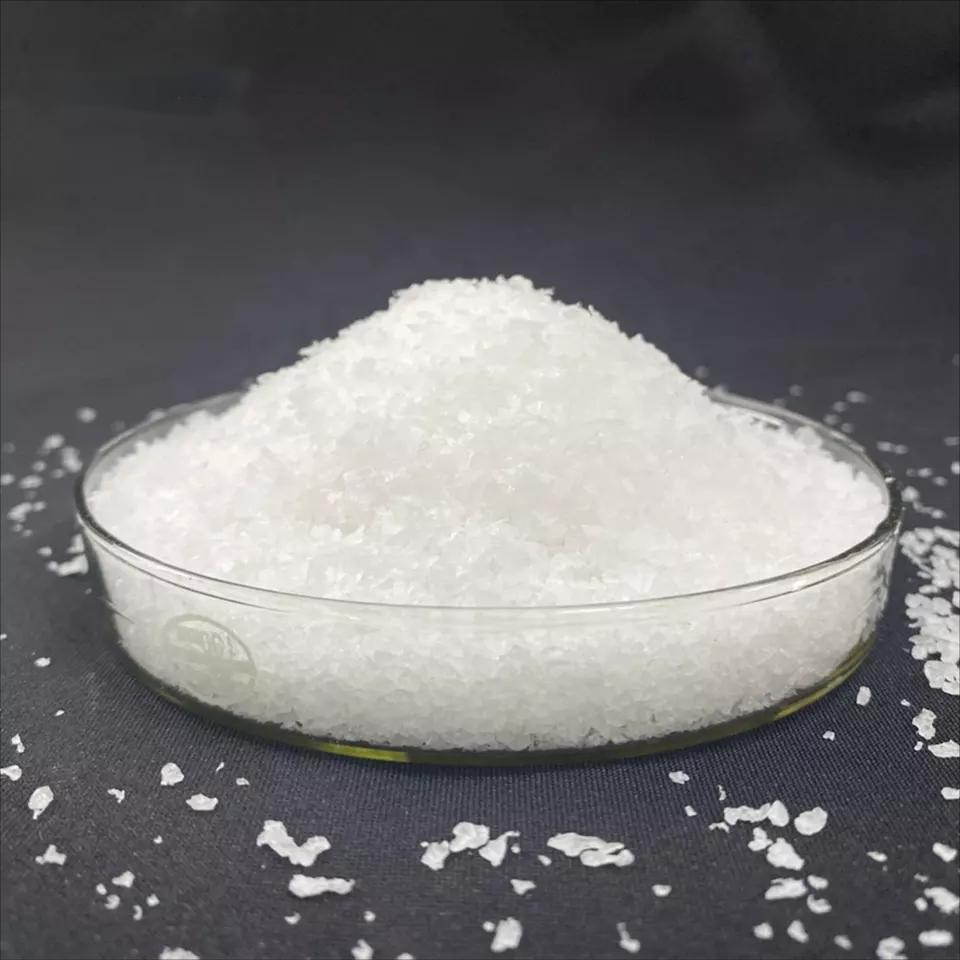

Poly(vinyl alcohol) (PVA) is a high-performance, water-soluble synthetic polymer valued for its strong film-forming, emulsifying, and adhesive properties. In industrial settings, grades such as BP24 and BP26 are commonly selected for coatings and adhesives where clarity, tensile strength, and controlled viscosity are essential. Naming conventions like PVA 2488, 1799, and 2699 generally indicate viscosity and degree-of-hydrolysis families that help formulators target tack, film strength, and water resistance. In practice, this means you can tune open time, cohesion, and bonding performance across porous substrates, fillers, and pigments.

For B2B buyers in the Chemical raw material and chemical product manufacturing industry—especially Synthetic resin manufacturing—PVA’s reliability in waterborne systems is critical. It dissolves in hot water to yield clear solutions suitable for emulsion polymerization (as a protective colloid), paper and textile binders, redispersible polymer powders, and architectural paints. Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd. manufactures and supplies consistent-quality PVA, backed by robust quality control and application support. Certificates of analysis and technical data are available to align the chosen PVA grade to your process window and product performance targets.

Benefits & Use Cases of Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint in Synthetic resin manufacturing

Within Synthetic resin manufacturing, PVA plays multiple roles. As a protective colloid in VAE, VEOVA, and acrylate emulsion polymerization, it stabilizes particles and controls particle size distribution for high-solids, low-VOC latexes. In adhesive and paint formulations, PVA 2488 and related grades deliver strong film formation, excellent pigment dispersion, and balanced adhesion to mineral, wood, paper, and textile substrates. PVA 1799 families are often selected to improve water resistance, while 2699-type grades support higher viscosity builds and cohesive strength in thicker films and gap-filling adhesive systems.

Key advantages include predictable dissolution, clean solutions with low gel content, and compatibility with common fillers and plasticizers. Film clarity, toughness, and barrier characteristics help coatings achieve better scrub resistance and reduced dust pick-up. Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd. brings deep formulation know-how to help you specify BP24/BP26 or 2488/1799/2699 families based on target solids, viscosity profile, and curing conditions. Whether you are scaling a new emulsion resin line or optimizing a mature adhesive SKU, tailored technical guidance shortens development cycles and stabilizes quality at production scale.

Cost, Maintenance & User Experience

Total cost of ownership for PVA hinges on dose efficiency, solution preparation, and manufacturing uptime. By selecting the right Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint grade, many plants reduce overall binder consumption while maintaining target viscosity and film strength, improving cost-per-ton of finished adhesive or paint. PVA’s predictable dissolution and stable viscosity can minimize rework and off-spec batches, reducing waste and energy consumption during mixing.

Maintenance is straightforward: store PVA powder in dry conditions, prepare solutions with controlled heating and agitation, and filter if your process requires ultra-low gel content. Users in the Chemical raw material and chemical product manufacturing industry report smooth wet-out, fast dissolution, and steady rheology over production shifts—translating into fewer line stops and consistent coating quality. Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd. supports implementation with handling guidance, recommended dissolution temperatures, and optimized addition sequences to streamline onboarding and maximize ROI.

Sustainability & Market Trends in manufacturing

Waterborne technologies are accelerating as regulations tighten on VOCs and formaldehyde in adhesives and paints. PVA is a natural fit: it is water-soluble, supports low-VOC formulations, and helps replace solvent-heavy systems without sacrificing performance. In Synthetic resin manufacturing, PVA-based stabilization for emulsion polymerization underpins the growth of eco-friendlier latex binders used in architectural coatings, packaging, and construction chemicals.

Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd. prioritizes responsible manufacturing with a focus on quality consistency, efficient resource use, and documentation that supports customer compliance frameworks. By offering PVA options across BP24/BP26 and 2488/1799/2699 families, the company enables formulators to meet sustainability targets—such as lower VOC, improved repulpability in paper applications, and reduced solvent demand—while safeguarding throughput and end-use performance. As the market continues to reward durable, low-emission materials, PVA remains a strategic component for B2B innovators.

Conclusion on Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint from Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.

For adhesives, paints, and emulsion resin manufacturing, Poly(vinyl alcohol) Bp26 pva bp24 Polymer pva 2488 1799 2699 pva chemical polyvinyl alcohol powder price for Adhesive/paint offers dependable film formation, adhesion, and stabilization with strong cost-performance. Backed by the expertise of Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd., buyers gain consistent quality and technical support that accelerate scale-up and safeguard product quality.

Contact us: email: yongfeng@yfhpmc.com

Visit our website: https://www.youngcel.com

-

Understanding Methyl 2 Hydroxyethyl Cellulose: Uses, Benefits & Industry InsightsNewsNov.24,2025

-

Hydroxyethyl Methyl Cellulose HEMC: Industrial Uses, Benefits & Future TrendsNewsNov.23,2025

-

HEMC Cellulose: Versatile & Sustainable Industrial Polymer | YoungcelNewsNov.23,2025

-

Methyl Hydroxyethyl Cellulose: Versatile Building Block for Industry & SustainabilityNewsNov.23,2025

-

CAS 9032 42 2: Understanding Polyvinyl Alcohol's Impact on Industry & SustainabilityNewsNov.22,2025

-

Hydroxyethyl Methyl Cellulose: Versatile Solutions for Modern Industry and SustainabilityNewsNov.22,2025