Understanding Redispersible Powder (RDP) and Its Applications

Redispersible powder (RDP) is a crucial material in the realm of construction and building materials, particularly in the formulation of adhesives, sealants, and other types of dry mortars. This versatile product plays a significant role in enhancing the performance characteristics of various applications and is increasingly gaining popularity due to its numerous benefits.

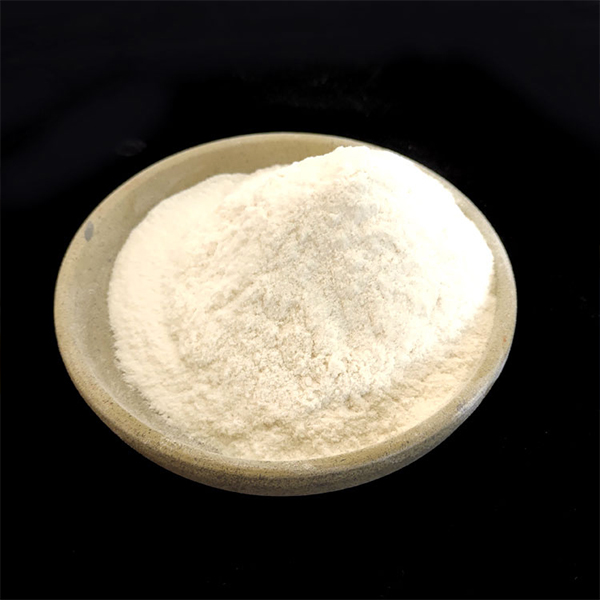

At its core, RDP is a white, free-flowing powder that results from the spray-drying of a polymer emulsion. When mixed with water, it re-disperses to form a cohesive film, which contributes to the improved adhesion, flexibility, and water resistance of the final product. Typical polymers used in RDP formulations include polyvinyl acetate (PVAc), styrene-acrylic copolymers, and ethylene-vinyl acetate (EVA).

Understanding Redispersible Powder (RDP) and Its Applications

Moreover, RDP is pivotal in the production of self-leveling compounds. These compounds are designed to create a flat and even surface, which is essential before laying flooring materials. The addition of RDP improves the flow characteristics of the compound and helps maintain workability, allowing for easier application. Additionally, it enhances adhesion to various substrates, ensuring a strong bond that lasts over time.

redispersible powder rdp

The use of RDP is not limited to adhesives and tile installations; it also finds applications in the manufacturing of plasters, skim coats, and renders. These products benefit from the improved workability and adhesion imparted by RDP. For instance, in plaster applications, RDP contributes to a smoother finish and reduced shrinkage, leading to fewer cracks and enhanced durability.

In addition to construction applications, RDP is also utilized in the production of paints and coatings. When incorporated into these formulations, it can improve the film formation, enhance water resistance, and provide better adhesion to surfaces. This makes RDP an excellent choice for exterior paints, which must withstand environmental challenges such as moisture and temperature fluctuations.

From an environmental perspective, RDP is beneficial because it can contribute to higher performance with lower amounts of polymer needed in formulations, which can ultimately lead to reduced VOC (Volatile Organic Compound) emissions. Many manufacturers are increasingly conscious of these factors, thus opting for RDP as a sustainable choice that does not compromise on performance.

In summary, redispersible powder is an essential component in the construction industry, offering significant enhancements to the performance of adhesives, mortars, and coatings. Its ability to improve adhesion, flexibility, and durability makes it a preferred choice among manufacturers. As the construction industry continues to evolve towards more sustainable practices, the role of RDP will likely grow, supporting innovations that enhance product performance while minimizing environmental impact. Understanding the benefits and applications of RDP is critical for professionals in the field, as it can lead to better construction practices and improved project outcomes.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025