Understanding Cellulose and HPMC A Comparative Insight

Cellulose, often regarded as one of nature's most abundant polysaccharides, is a critical biopolymer primarily found in the cell walls of plants. Its structure consists of long chains of glucose units linked by β-1,4-glycosidic bonds, which confer to it unique properties such as high tensile strength and chemical stability. Cellulose forms the backbone of plant structure and plays a vital role in the dietary fiber essential for human health.

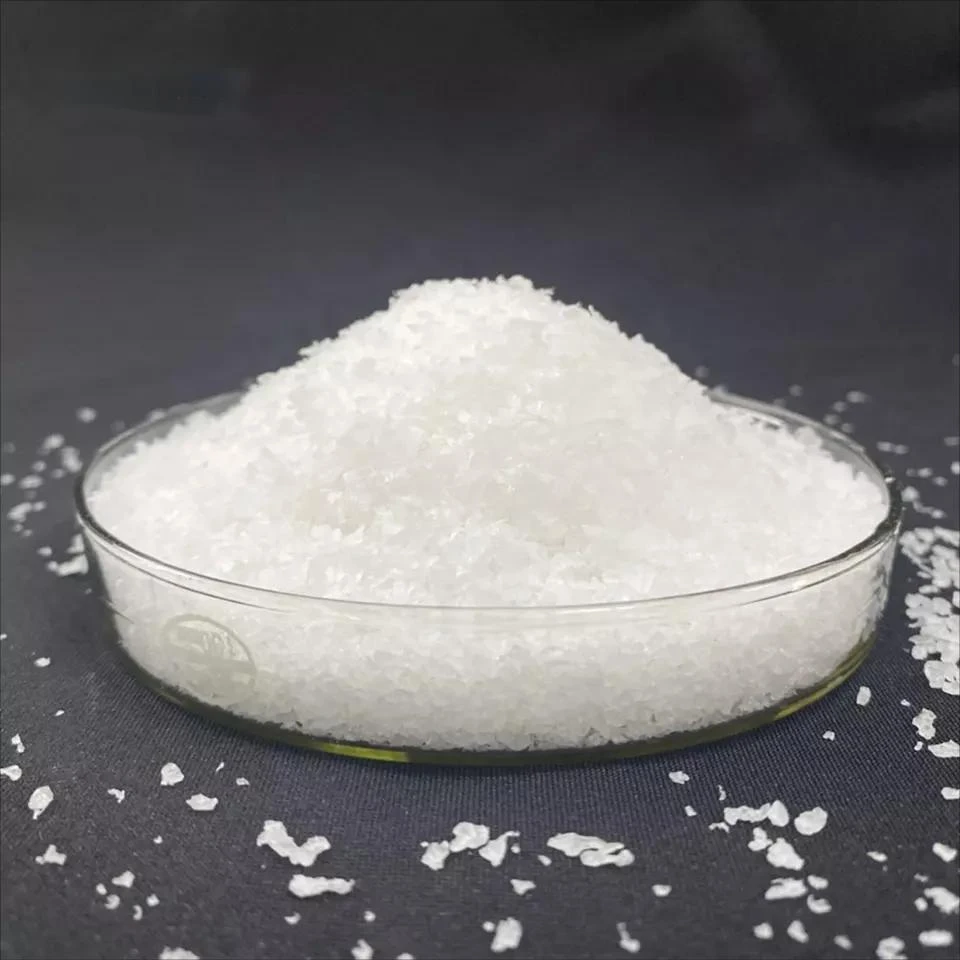

Hydroxypropyl Methylcellulose (HPMC), on the other hand, is a modified derivative of cellulose. By introducing hydroxypropyl and methyl groups to the cellulose chain, HPMC possesses enhanced solubility in water and improved performance characteristics compared to its unmodified counterpart. This modification not only affects its solubility but also enhances its film-forming capabilities, making it highly valuable in various industries.

Properties and Applications

Cellulose and HPMC share some fundamental properties, such as their biocompatibility and non-toxicity, which make them suitable for use in dietary supplements, pharmaceuticals, and food products. However, their applications diverge significantly due to their structural differences.

Cellulose is primarily utilized as a texturizer, bulking agent, and stabilizer in food products. It is also widely used in the pharmaceutical industry as an excipient in tablets and capsules due to its ability to control the release of active ingredients.

In contrast, HPMC has found a niche in a wider array of applications. Its water solubility allows it to be utilized in various formulations, including adhesives, ceramics, and coatings. In the construction industry, HPMC is used as a thickening agent in mortars and adhesives, enhancing workability and adhesion. Furthermore, HPMC is increasingly popular in the cosmetic industry, where its film-forming properties contribute to the manufacturing of hair products and skincare formulations.

cellulos hpmc

Health Benefits

From a health perspective, cellulose serves as an essential component of dietary fiber, helping to regulate digestion and prevent constipation. It contributes to a healthy gut microbiome by acting as a prebiotic, promoting the growth of beneficial gut bacteria.

HPMC, while not directly contributing fiber, serves as an effective bulking agent in various dietary supplements. It is often used in weight management products due to its ability to enhance satiety, promoting a feeling of fullness without adding significant calories. Moreover, HPMC is utilized in gluten-free baking, contributing to the texture and moisture retention that is typically challenging in gluten-free products.

Environmental Considerations

Both cellulose and HPMC are derived from renewable resources, aligning with increasing global sustainability efforts. The production of cellulose is often considered environmentally friendly, as it can be extracted from various agricultural waste products and secondary resources. HPMC, being a synthetic derivative, may involve chemical processes; however, its biodegradability and low environmental impact during usage make it a favorable choice in many applications.

Conclusion

In summary, cellulose and Hydroxypropyl Methylcellulose both offer distinctive benefits and applications across various fields, from food and pharmaceuticals to construction and cosmetics. Understanding their properties and differences is crucial for leveraging their potential. As industries continue to evolve towards sustainability and health, the roles of these biopolymers will undoubtedly expand, making them vital components of future innovations. Embracing both cellulose and HPMC can lead to improved formulations that support health and align with environmental goals, marking a significant stride towards a more sustainable future.

-

The Application and Significance of Construction RdpNewsMay.19,2025

-

Industrial Grade HpmcNewsMay.19,2025

-

Building Coating Adhesive Building Coating Adhesive HpmcNewsMay.19,2025

-

Application Of Hpmc For Detergent For Detergent In DetergentsNewsMay.19,2025

-

Application Of Hpmc Cellulose In Cement-Based MaterialsNewsMay.19,2025

-

Application Of High Quality Hpmc For Construction In The Field Of ConstructionNewsMay.19,2025