The Role of HPMC Manufacturers in the Modern Industry

Hydroxypropyl Methylcellulose (HPMC) has become an indispensable component across various industries, including pharmaceuticals, construction, food and personal care. As a non-ionic, water-soluble polymer derived from cellulose, HPMC is prized for its diverse functionalities, such as acting as a thickening agent, emulsifier, and film-forming agent. This versatility underscores the critical role that HPMC manufacturers play in catering to a growing demand for specialty chemicals.

Understanding HPMC and Its Applications

HPMC is synthesized through the etherification of cellulose, a natural polymer extracted from plant cell walls. By introducing hydroxypropyl and methyl groups into the cellulose structure, manufacturers enhance its solubility and thermal stability, fostering a range of applications. In the pharmaceutical sector, HPMC is widely used as an excipient in oral drug formulations, providing controlled release properties that enhance therapeutic efficacy.

In the construction industry, HPMC serves as an essential additive in cement and tile adhesives. Its water-retaining capabilities are vital for preventing premature drying of mortars, allowing for better workability and adhesion. Furthermore, in the food industry, HPMC acts as a thickening agent and stabilizer, contributing to the texture and consistency of various products, including sauces and bakery goods.

The cosmetic and personal care industry also benefits from HPMC, where it is employed in creams, lotions, and gels. Its ability to form films and enhance the viscosity of formulations makes it a popular choice among cosmetic manufacturers aiming for high-quality products.

The Market Dynamics of HPMC Manufacturing

As industries continue to evolve, the demand for HPMC is projected to rise significantly. Market dynamics indicate a robust growth trajectory for HPMC manufacturers due to the increasing consumer preference for high-performance and multifunctional products.

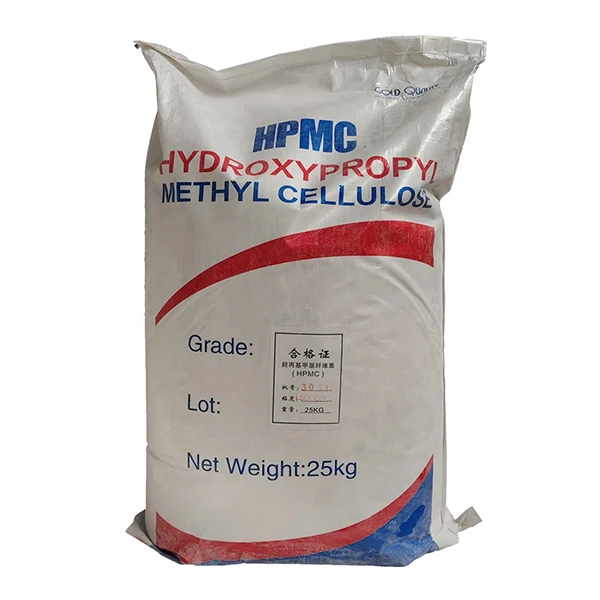

hpmc manufacturer

Globalization has led to heightened competition among manufacturers. Countries like China, the United States, and Germany have emerged as leading producers of HPMC. Manufacturers are now focusing on innovation, investing in research and development to produce bio-based and sustainable HPMC, which aligns with the global trend towards eco-friendly solutions.

Additionally, collaboration with end-users and industry experts is gaining importance. Manufacturers are increasingly engaging in partnerships that facilitate better understanding of market needs, enabling them to tailor their products for specific applications. This customer-centric approach not only drives innovation but also enhances brand loyalty and customer satisfaction.

Challenges Facing HPMC Manufacturers

Despite the promising growth, HPMC manufacturers encounter several challenges. The fluctuating prices of raw materials, primarily cellulose, can impact production costs and market pricing strategies. Moreover, stringent regulations governing product formulations, particularly in pharmaceuticals and food, necessitate compliance and quality assurance, adding further complexity to the manufacturing process.

Another challenge is the increasing competition from alternative products that may offer lower costs. Manufacturers must be proactive in differentiating their HPMC products, emphasizing quality, performance, and sustainability.

The Future Outlook

The future of HPMC manufacturing looks bright, driven by ongoing advancements in technology and increasing awareness of the benefits of HPMC across diverse sectors. Manufacturers are anticipated to adopt automation and smart manufacturing practices to enhance efficiency and reduce operational costs.

In conclusion, HPMC manufacturers are vital players in the supply chain of many industries, providing essential materials that meet the demands of modern consumers. As the market continues to expand, adaptability, innovation, and a commitment to sustainability will be key factors that determine the success of HPMC manufacturing in the coming years. With the right strategies in place, HPMC manufacturers can not only thrive in a competitive landscape but also contribute significantly to the development of sustainable industry practices.

-

The Application and Significance of Construction RdpNewsMay.19,2025

-

Industrial Grade HpmcNewsMay.19,2025

-

Building Coating Adhesive Building Coating Adhesive HpmcNewsMay.19,2025

-

Application Of Hpmc For Detergent For Detergent In DetergentsNewsMay.19,2025

-

Application Of Hpmc Cellulose In Cement-Based MaterialsNewsMay.19,2025

-

Application Of High Quality Hpmc For Construction In The Field Of ConstructionNewsMay.19,2025