Additive for Putty Enhancing Performance and Versatility

In the world of construction and manufacturing, putty has long been regarded as a versatile and essential material. Typically used for filling gaps, repairing surfaces, and creating a smooth finish, putty serves various purposes across multiple industries. However, the introduction of additives into putty formulations has significantly transformed its performance and broadened its applications. This article explores the various types of additives for putty, their benefits, and their impact on different industries.

Understanding Additives

Additives are substances added to a material to enhance its properties and performance. In the case of putty, these additives can improve workability, drying time, adhesion, durability, and even aesthetic qualities. By carefully selecting and incorporating additives, manufacturers can tailor putty formulations to meet specific application requirements and environmental conditions.

Types of Additives for Putty

1. Fillers Fillers are commonly used to enhance the volume and consistency of putty. Materials such as calcium carbonate, talc, or silica can be added to create a smoother texture and improve bulk properties. Fillers can also influence the weight, strength, and drying characteristics of the putty, making it more suitable for diverse tasks.

2. Binders Binders are essential additives that help hold the components of putty together. Synthetic resins, polymers, or natural substances like starch can be used as binders to enhance adhesion and flexibility. A strong binder not only improves the structural integrity of the putty but also contributes to its resilience against environmental factors, such as moisture and temperature fluctuations.

3. Plasticizers Plasticizers are substances that increase the plasticity or fluidity of putty, making it easier to work with. Common plasticizers include phthalates and certain glycol esters. By reducing viscosity, plasticizers allow for smooth application and the ability to achieve intricate shapes without cracking or losing cohesiveness.

4. Accelerators and Retarders The curing process of putty can be adjusted with the use of accelerators and retarders. Accelerators speed up the drying time, which is particularly advantageous in time-sensitive projects. Conversely, retarders prolong the working time of putty, providing additional flexibility for intricate tasks or larger areas that require detailed work.

5. Colorants and Fillers for Aesthetics For decorative applications, colorants can be mixed into putty to achieve desired shades and finishes. This is particularly useful in restoration projects where matching the original colors is essential. Specialty fillers can also create textured finishes, allowing for artistic applications.

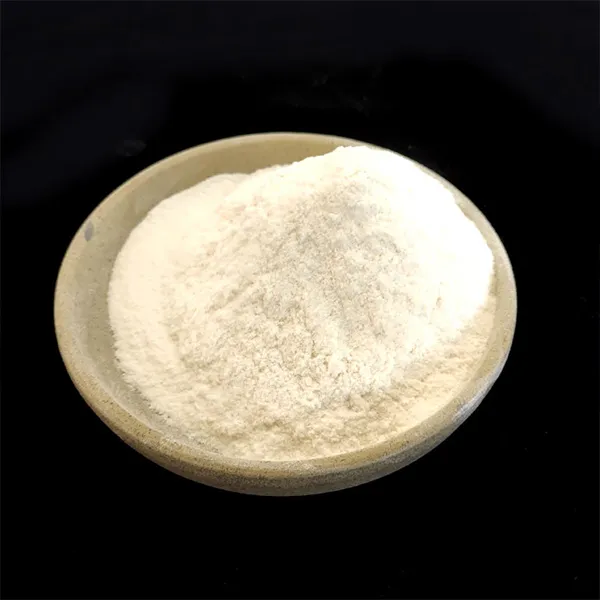

additive for putty

Benefits of Using Additives

The inclusion of additives in putty formulations offers a range of benefits

- Enhanced Performance Additives can improve the strength and durability of putty, making it suitable for high-stress applications, such as in construction and automotive repairs.

- Versatility With the ability to modify properties like consistency, drying time, and adhesion, putty can be adapted for a wide range of applications—from simple repairs to complex installations.

- Improved Workability Additives such as plasticizers and fillers can make putty easier and more enjoyable to work with, reducing labor time and improving results.

- Environmental Resistance Additives can enhance the putty's ability to withstand environmental stressors, including moisture, temperature changes, and UV exposure, leading to longer-lasting repairs.

Applications Across Industries

The advancements in putty formulations due to the inclusion of additives have led to expanded applications across various industries. In construction, putties are used for drywall finishing, flooring installations, and as adhesives for tiles and panels. In the automotive industry, specialized putties are utilized for bodywork and repairs, ensuring a smooth finish that is resistant to weather conditions.

Conclusion

Additives for putty have revolutionized the way contractors, manufacturers, and artisans approach their work. By understanding and leveraging these enhancements, users can achieve superior results that are tailored to their specific needs. Whether for construction, arts and crafts, or industrial applications, the future of putty looks promising, thanks to the continuous innovation surrounding additives. As industries evolve and demand higher performance materials, the role of additives in putty will likely become even more critical.

-

The Application and Significance of Construction RdpNewsMay.19,2025

-

Industrial Grade HpmcNewsMay.19,2025

-

Building Coating Adhesive Building Coating Adhesive HpmcNewsMay.19,2025

-

Application Of Hpmc For Detergent For Detergent In DetergentsNewsMay.19,2025

-

Application Of Hpmc Cellulose In Cement-Based MaterialsNewsMay.19,2025

-

Application Of High Quality Hpmc For Construction In The Field Of ConstructionNewsMay.19,2025