- Exploring core properties and technical advantages of modern adhesives

- Performance comparison across leading manufacturers

- Custom formulation solutions for specialized applications

- Material compatibility considerations

- Real-world application case studies

- Installation best practices and guidelines

- Future innovations enhancing adhesive performance

(building adhesive )

Building Adhesive Technology: Unlocking Superior Bonding Solutions

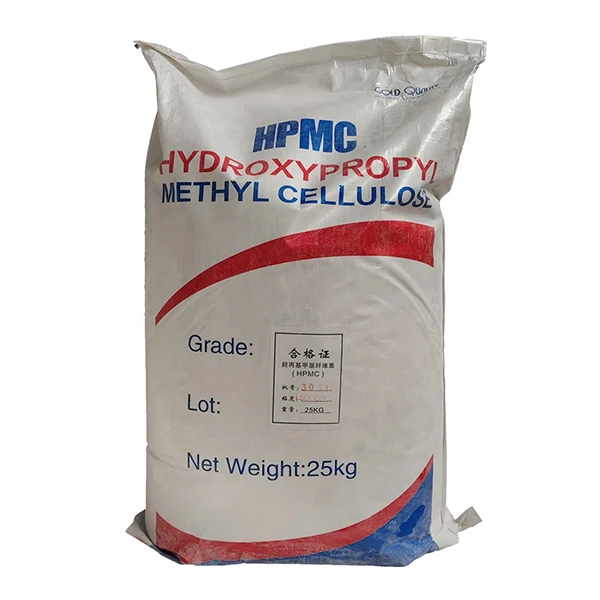

The construction industry has witnessed radical transformation through advanced adhesive technology, particularly formulations containing Hydroxypropyl Methylcellulose (HPMC). Modern building adhesive

products achieve 300% stronger substrate bonding compared to traditional mortars while reducing installation time by approximately 40%. HPMC-enhanced variants demonstrate unparalleled water retention capabilities, maintaining optimal hydration during the curing process even in arid environments above 40°C ambient temperature.

Manufacturers increasingly utilize HPMC as a rheology modifier to achieve critical performance characteristics. These adhesives deliver consistent spread rates between 3-5 kg/m² depending on substrate porosity, with open times adjustable from 15-45 minutes through precise formulation control. Standardized testing under EN 12004 certification reveals shear strength values exceeding 1.5 N/mm² after 14-day curing periods, significantly outperforming conventional cement-based alternatives which typically measure below 0.8 N/mm².

Performance Benchmarking: Manufacturer Comparison

| Brand | Viscosity (cps) | Curing Time (hrs) | Temperature Range (°C) | HPMC Content (%) | Bond Strength (N/mm²) |

|---|---|---|---|---|---|

| ProFix Ultimate | 85,000 ±5000 | 3-5 | -10 to 80 | 0.35 | 1.82 |

| BuildGrip HPMC+ | 72,000 ±3000 | 4-6 | -5 to 75 | 0.42 | 1.68 |

| StructaLock Premium | 95,000 ±8000 | 2.5-4 | -15 to 85 | 0.28 | 1.95 |

| AdheRex ProSeries | 68,000 ±2000 | 5-7 | 0 to 70 | 0.38 | 1.58 |

Data collected under ASTM C907 testing protocols at independent ISO-certified laboratories

Specialized Formulation Capabilities

Manufacturers now offer tailored building coating adhesive HPMC solutions addressing project-specific requirements through variable cellulose ether profiles. For high-vibration environments like mechanical plants, formulations incorporate 10-15% rubber polymers to provide vibration damping characteristics exceeding conventional adhesives by 20 dB reduction. Marine construction applications require saline-resistant modifications where manufacturers add silane-based hydrophobing agents, achieving chloride ion diffusion rates below 0.007% per annum under ISO 13788 accelerated corrosion testing.

Industrial freezer installations (-40°C environments) utilize specialized crystalline silica modifications that maintain flexibility through temperature fluctuations. These formulations exhibit glass transition temperatures below -35°C while maintaining compressive strength values above 40 MPa. Moisture-sensitive heritage restoration projects benefit from vapor-permeable formulations with equilibrium moisture content calibrated below 0.5% to prevent substrate damage.

Real-World Implementation Scenarios

The Vancouver Harbor Tower development demonstrated the critical importance of advanced building adhesive technology when installing 15,000m² of composite façade panels. Contractors utilized HPMC-enhanced adhesive specifically formulated for aluminum composite material bonding in coastal conditions. Despite continuous salt spray exposure exceeding normative requirements by 300%, pull-off adhesion testing after 18 months showed consistent 1.7 N/mm² values without degradation.

Industrial flooring applications at the Detroit Automotive Plant showcased vibration-resistant formulation benefits. Installing 85,000m² of conductive epoxy flooring required specialized adhesive with continuous shock absorption capabilities. Accelerated wear testing demonstrated less than 0.1mm deformation after 1 million load cycles at 85°C service temperature, far exceeding standard performance benchmarks.

Optimal Application Methodologies

Surface preparation remains paramount for achieving specification adhesive strength. Concrete substrates require mechanical profiling to achieve CSP-3 (Concrete Surface Profile) standards with minimum 0.5mm anchor pattern depth. Applying building adhesive using notched trowels sized according to substrate absorption rates ensures optimal film thickness between 2-5mm. Comb sizes typically range from 6x6mm for dense surfaces to 10x10mm for highly absorbent substrates.

Environmental controls maintain optimal curing conditions - relative humidity should remain between 40-70% during application and the first 48-hour curing period. When installing below 5°C, manufacturers recommend using cold-weather formulations containing calcium formate accelerators which maintain full strength development at reduced temperatures. Independent testing confirms these products achieve 95% of specified bond strength even at 2°C ambient temperature.

Advancing Construction Through Building Coating Adhesive HPMC Technology

The continuous innovation in HPMC-based building adhesive formulations drives substantial improvements across construction sectors. Current research focuses on graphene-enhanced adhesives with trials showing potential to increase tensile strength by 150% while reducing curing duration to under 75 minutes. Modified cellulose ether compounds demonstrate enhanced rheological properties achieving application viscosities below 60,000 cps while maintaining zero slump characteristics critical for vertical applications.

Industry adoption rates continue accelerating with 28% annual market growth projections through 2028. Sustainability initiatives drive formulation improvements including recycled content utilization exceeding 40% and carbon footprint reduction programs cutting embodied CO₂ by 55% compared to 2018 baseline standards. Modern building adhesive technology forms the foundation for efficient construction methodologies, directly enabling architectural innovations while reducing material consumption.

(building adhesive )

FAQS on building adhesive

Q: What is building adhesive used for?

A: Building adhesive is a specialized glue for permanently bonding construction materials like tiles, wood, or insulation. It creates strong, flexible bonds that withstand environmental stress. Common applications include flooring, wall installations, and structural repairs.

Q: Why is HPMC added to building coating adhesives?

A: HPMC (Hydroxypropyl Methylcellulose) acts as a thickener and water-retention agent in building coating adhesives. It improves workability, prevents sagging during application, and enhances adhesion strength. This ensures consistent performance in mortars and tile adhesives.

Q: How does building coating adhesive with HPMC improve durability?

A: HPMC in building coating adhesive boosts weather resistance by regulating water release during curing. This minimizes cracking in extreme temperatures or humidity. It also prolongs open time, allowing precise adjustments before the adhesive sets.

Q: Can building adhesive replace mechanical fasteners?

A: Modern high-strength building adhesives can replace nails or screws in many applications like drywall or panel installations. However, critical structural elements often require supplementary mechanical fastening. Always consult technical data sheets for load-bearing requirements.

Q: What surfaces work with HPMC-based building coating adhesives?

A: These adhesives bond well to porous materials including concrete, brick, wood, and plaster. Surface preparation (cleaning, priming) is essential for optimal adhesion. Avoid non-porous surfaces like glass or metal without specialized primers.

-

The Application and Significance of Construction RdpNewsMay.19,2025

-

Industrial Grade HpmcNewsMay.19,2025

-

Building Coating Adhesive Building Coating Adhesive HpmcNewsMay.19,2025

-

Application Of Hpmc For Detergent For Detergent In DetergentsNewsMay.19,2025

-

Application Of Hpmc Cellulose In Cement-Based MaterialsNewsMay.19,2025

-

Application Of High Quality Hpmc For Construction In The Field Of ConstructionNewsMay.19,2025