Jan . 17, 2025 02:30

Back to list

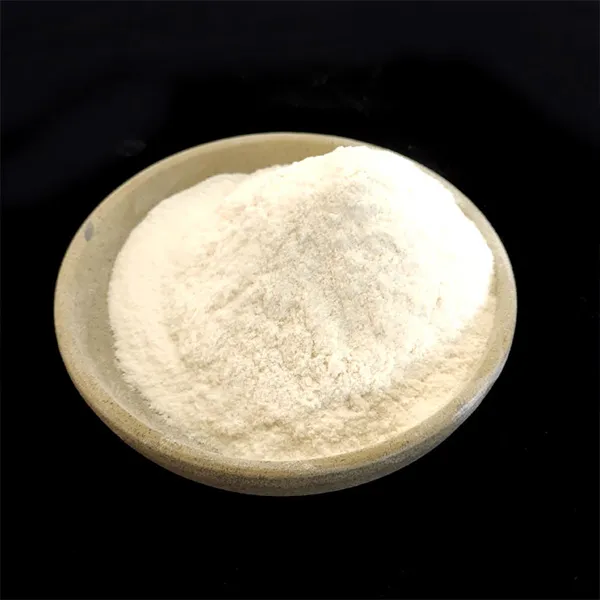

ceramic adhesives

Ceramic adhesives have emerged as an indispensable tool for modern construction and household repairs. These versatile bonding agents have garnered attention not only for their high-performance attributes but also for their adaptability across various applications. For industry professionals and DIY enthusiasts, understanding the nuances of ceramic adhesives can enhance the longevity and durability of projects.

From an expertise standpoint, selecting the right ceramic adhesive involves assessing factors such as temperature resistance, curing time, and flexibility. Industry experts recommend formulations designed to handle specific environmental conditions and substrate materials, emphasizing the importance of assessing the project's demands thoroughly. For high-temperature applications, such as furnace or kiln repairs, adhesives with silica or alumina silicate compositions are preferred for their ability to maintain integrity under extreme conditions. Authoritativeness in the field of ceramic adhesives is bolstered by industry standards and certifications that validate product quality and safety. Products adhering to international standards such as ISO and ASTM ensure consistency and reliability, giving users confidence in their selected adhesive. Consulting technical datasheets and manufacturer guidelines further supports informed decision-making and proper application techniques, minimizing the risk of failure. Trustworthiness in the use of ceramic adhesives stems from both the product’s reputation and the installer’s proficiency. Professionals in the field often undergo training and certification programs that ensure adherence to best practices, thereby enhancing the credibility of their work. For consumers, choosing reputable brands with positive testimonials and comprehensive support services adds an additional layer of assurance. In summary, ceramic adhesives are a cornerstone of modern adhesive technology, offering unparalleled strength and versatility for a multitude of applications. Whether used in industrial settings or home improvement projects, their benefits are maximized through informed selection and expert application. Through rigorous adherence to industry standards and ongoing professional development, the reliability and efficiency of ceramic adhesives continue to be substantiated, making them a trusted choice for bonding ceramic and other materials in demanding environments.

From an expertise standpoint, selecting the right ceramic adhesive involves assessing factors such as temperature resistance, curing time, and flexibility. Industry experts recommend formulations designed to handle specific environmental conditions and substrate materials, emphasizing the importance of assessing the project's demands thoroughly. For high-temperature applications, such as furnace or kiln repairs, adhesives with silica or alumina silicate compositions are preferred for their ability to maintain integrity under extreme conditions. Authoritativeness in the field of ceramic adhesives is bolstered by industry standards and certifications that validate product quality and safety. Products adhering to international standards such as ISO and ASTM ensure consistency and reliability, giving users confidence in their selected adhesive. Consulting technical datasheets and manufacturer guidelines further supports informed decision-making and proper application techniques, minimizing the risk of failure. Trustworthiness in the use of ceramic adhesives stems from both the product’s reputation and the installer’s proficiency. Professionals in the field often undergo training and certification programs that ensure adherence to best practices, thereby enhancing the credibility of their work. For consumers, choosing reputable brands with positive testimonials and comprehensive support services adds an additional layer of assurance. In summary, ceramic adhesives are a cornerstone of modern adhesive technology, offering unparalleled strength and versatility for a multitude of applications. Whether used in industrial settings or home improvement projects, their benefits are maximized through informed selection and expert application. Through rigorous adherence to industry standards and ongoing professional development, the reliability and efficiency of ceramic adhesives continue to be substantiated, making them a trusted choice for bonding ceramic and other materials in demanding environments.

Next:

Latest news

-

The Application and Significance of Construction RdpNewsMay.19,2025

-

Industrial Grade HpmcNewsMay.19,2025

-

Building Coating Adhesive Building Coating Adhesive HpmcNewsMay.19,2025

-

Application Of Hpmc For Detergent For Detergent In DetergentsNewsMay.19,2025

-

Application Of Hpmc Cellulose In Cement-Based MaterialsNewsMay.19,2025

-

Application Of High Quality Hpmc For Construction In The Field Of ConstructionNewsMay.19,2025