HPMC for Cement Enhancing Performance and Sustainability

Hydroxypropyl Methylcellulose (HPMC) is a versatile cellulose ether that has gained significant traction in the construction industry, particularly in the formulation of cement-based materials. Its unique properties make it an invaluable ingredient, contributing to the performance, workability, and sustainability of cement mixtures.

What is HPMC?

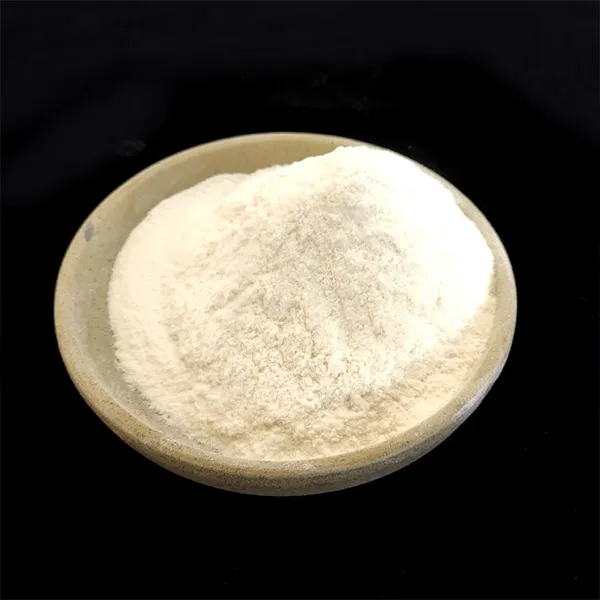

HPMC is a non-ionic cellulose ether that is derived from natural cellulose. It is synthesized through the modification of cellulose with propylene oxide and methyl chloride. The result is a white, odorless powder that is soluble in water and forms a clear gel-like substance when hydrated. This characteristic is vital for numerous applications in the construction industry.

Role of HPMC in Cement-Based Materials

1. Improved Workability One of the primary benefits of adding HPMC to cement formulations is its ability to enhance workability. When mixed with water, HPMC increases the viscosity of the slurry, making it easier to handle and apply. This is particularly important for plastering and tiling applications, where a smooth, workable mixture is essential for achieving a high-quality finish.

2. Extended Open Time HPMC contributes to the extended open time of cement mixtures. Open time refers to the period during which the mixture remains workable before it begins to set. By delaying the setting process, HPMC allows more time for application, which is crucial in large-scale projects where timing can be critical.

hpmc for cement

3. Enhanced Adhesion The inclusion of HPMC in cement formulations can significantly improve the adhesion properties of the material. This is particularly beneficial for tile adhesives and other bonding agents, ensuring that they maintain a strong grip on surfaces even under challenging conditions.

4. Water Retention Another key property of HPMC is its ability to retain water within the mixture. This is vital for hydration, the chemical process through which cement hardens. By preventing rapid evaporation of water, HPMC ensures that the cement can properly cure, resulting in a stronger final product.

5. Crack Resistance The elasticity imparted by HPMC also contributes to crack resistance in cement-based products. As the material cures and dries, it can experience shrinkage. HPMC's water-retentive and flexible properties help mitigate this issue, leading to fewer cracks and better longevity of the material.

Environmental Considerations

In the face of increasing environmental concerns, the use of HPMC in cement formulations offers a pathway to more sustainable construction practices. HPMC is derived from renewable resources, and its ability to enhance performance means that smaller quantities of cement can be used without sacrificing quality. This reduction in cement usage directly correlates with a decrease in carbon emissions associated with cement production, making HPMC a key player in promoting greener building practices.

Conclusion

Hydroxypropyl Methylcellulose represents a breakthrough in the formulation of cement-based materials. Its multifaceted benefits, including improved workability, extended open time, enhanced adhesion, water retention, and crack resistance, make it an indispensable ingredient in modern construction. Moreover, the environmental advantages it offers align with the industry's push towards sustainability. As the construction sector continues to evolve, the role of HPMC in cement formulations will likely expand, paving the way for more efficient and eco-friendly building solutions.

-

The Application and Significance of Construction RdpNewsMay.19,2025

-

Industrial Grade HpmcNewsMay.19,2025

-

Building Coating Adhesive Building Coating Adhesive HpmcNewsMay.19,2025

-

Application Of Hpmc For Detergent For Detergent In DetergentsNewsMay.19,2025

-

Application Of Hpmc Cellulose In Cement-Based MaterialsNewsMay.19,2025

-

Application Of High Quality Hpmc For Construction In The Field Of ConstructionNewsMay.19,2025