The Role of Chemical Auxiliary Agents in Modern Industries

Chemical auxiliary agents are essential materials that play a crucial role in various industrial processes. These agents are not the main components of the final product but are pivotal in enhancing the performance and efficiency of other chemicals involved in manufacturing. From textiles to pharmaceuticals, chemical auxiliary agents are ubiquitous and have a profound impact on product quality, production efficiency, and overall environmental sustainability.

At its core, the term chemical auxiliary agent refers to substances added to a production process to assist in achieving a desired outcome. They can be categorized into several groups depending on their function. For example, in the textile industry, auxiliary agents such as surfactants, antifoams, and dyes facilitate processes like dyeing and finishing. These agents help improve the uniformity of dye application, minimize foam generation, and enhance the fabric's feel and appearance.

In the realm of construction, chemical auxiliary agents are used to enhance the properties of concrete and masonry. Plasticizers and superplasticizers, for instance, improve the workability of concrete, allowing it to be molded into complex shapes without sacrificing strength. Additionally, retarders and accelerators can alter the curing time of concrete, providing flexibility in construction schedules.

Pharmaceutical manufacturing also heavily relies on auxiliary agents. They are used to stabilize formulations, enhance solubility, and improve the bioavailability of active pharmaceutical ingredients (APIs). This ensures that medications work effectively in the body. Excipients, which are inactive substances formulated alongside the active ingredient, often serve as chemical auxiliary agents. They contribute to the stability, release properties, and overall effectiveness of the final medicinal product.

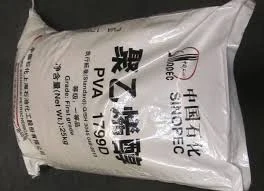

chemical auxiliary agent

Moreover, in the context of environmental sustainability, chemical auxiliary agents can assist in reducing waste and minimizing the use of harmful substances. For example, in the field of cleaning agents and detergents, enzymatic auxiliary agents have been increasingly employed to enhance cleaning efficiency at lower temperatures and with less water. These enzymes break down organic stains, thereby reducing the need for harsher chemicals that may have negative environmental impacts.

The production of chemical auxiliary agents is itself a significant industrial process. Their production often involves complex chemical reactions and processes to ensure that they meet specific performance criteria. Quality control and regulatory compliance are paramount, given that these agents can significantly influence the properties of the final product. Industries must adhere to strict guidelines set forth by regulatory bodies to ensure safety and effectiveness.

Innovation in the field of chemical auxiliary agents has been a driving force in many industries. Research and development efforts are continually focused on discovering new formulations that enhance product performance while also addressing sustainability challenges. For instance, biobased auxiliary agents derived from renewable resources are becoming increasingly popular, lowering the carbon footprint of various manufacturing processes.

The global market for chemical auxiliary agents is vast and is expected to continue growing, driven by the expanding demand across multiple sectors. The Asia-Pacific region, in particular, is projected to see significant growth due to its booming manufacturing industries and increasing investments in research and technology.

In conclusion, chemical auxiliary agents are often overlooked yet play a fundamental role in numerous industries. Their ability to enhance processes, improve product attributes, and contribute to sustainability makes them indispensable in today's manufacturing landscape. As industries evolve and face new challenges, the development and implementation of innovative chemical auxiliary agents will continue to be a pivotal aspect of ensuring efficiency, quality, and environmental responsibility. The ongoing research and commitment to improving these agents will undoubtedly shape the future of manufacturing and product development across the globe.