The Key Chemicals for Making Cement

Cement is one of the most commonly used construction materials in the world, serving as a critical binder in the production of concrete and mortar. The manufacturing of cement involves a careful selection and combination of raw materials, primarily limestone and clay, along with various other chemicals that enhance the properties of the final product. This article explores the key chemicals involved in the cement-making process.

1. Limestone (Calcium Carbonate)

Limestone is the primary raw material for cement production, primarily composed of calcium carbonate (CaCO3). When heated in a kiln, limestone undergoes a transformation, decomposing into lime (calcium oxide, CaO) and carbon dioxide (CO2). This process, known as calcination, is crucial in the production of clinker, the intermediate product in cement manufacturing.

2. Clay (Silica and Alumina Sources)

Clay serves as another essential ingredient in cement production, providing silica (SiO2) and alumina (Al2O3). These compounds play a vital role in the formation of various phases within the cement structure. The right balance of silica, alumina, and iron oxide is critical for creating the desired chemical composition of the cement. When combined with lime, these materials form silicates and aluminates during high-temperature sintering, contributing to the strength and durability of the resultant cement.

3. Iron Ore

Iron ore, primarily consisting of iron oxides, is another important raw material in cement production. It is typically added in small quantities to control the iron content in the clinker. The presence of iron enhances the cement's color and influences the hydration process, enabling better setting times and improving long-term strength.

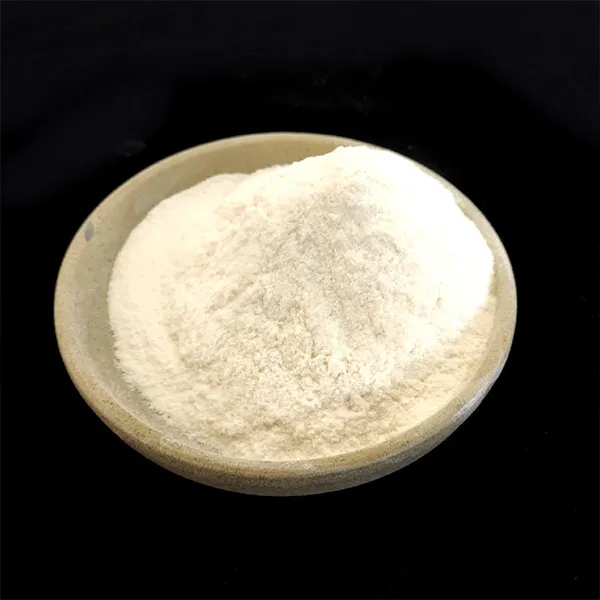

chemicals for making cement

4. Gypsum

Gypsum (calcium sulfate dihydrate, CaSO4·2H2O) is an essential additive in the final stages of cement manufacturing. Following the clinkering process, gypsum is ground with the clinker to control the setting time of the cement. Without gypsum, cement would set too quickly, making it challenging to work with during construction. The typical addition of gypsum to clinker ranges from 3% to 5%, ensuring appropriate setting characteristics.

5. Additives and Mineral Admixtures

In addition to the primary chemicals mentioned, various additives and mineral admixtures are often incorporated during the cement manufacturing process. These materials include fly ash, slag, and natural pozzolans, which enhance the performance of cement. For instance, fly ash, a byproduct from coal combustion, can improve the workability and durability of concrete while reducing the overall carbon footprint. Similarly, ground granulated blast-furnace slag (GGBS) can replace a portion of the clinker, leading to a reduction in greenhouse gas emissions associated with cement production.

6. Chemical Activators

Chemical activators, such as sodium silicate and sodium hydroxide, are sometimes used to improve the reactivity of certain types of cement, like alkali-activated cements. These activators can enhance the strength and durability of the final product, making it suitable for specific construction applications.

Conclusion

The chemistry behind cement production is complex yet fascinating. The combination of key raw materials, including limestone, clay, iron ore, and additives, results in a product that is fundamental to modern construction. Understanding the role of these chemicals helps manufacturers optimize the cement production process, creating materials that meet the evolving demands of infrastructure development while also addressing environmental concerns. As the industry continues to advance, innovative chemical solutions will likely emerge, further enhancing the sustainability and performance of cement.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025