Understanding HPMC Mortar The Key to Sustainable Construction

In recent years, the construction industry has witnessed a significant shift towards sustainable practices and materials. One of the standouts among these modern materials is Hydroxypropyl Methylcellulose (HPMC) mortar. This innovative product is rapidly gaining popularity due to its numerous advantages, which cater to both builders' needs and the growing demand for eco-friendly solutions.

What is HPMC?

HPMC is a plant-derived polymer that is widely used as a thickening agent, binder, and stabilizer in various applications. Its water-retention properties and versatility make it a prime candidate for incorporation into mortar formulations. When mixed with cement, sand, and water, HPMC enables the creation of a mortar that not only enhances workability but also improves overall performance.

Benefits of HPMC Mortar

1. Enhanced Workability One of the primary benefits of HPMC mortar is its excellent workability. The inclusion of HPMC allows for extended open time, making it easier for masons and contractors to work with the material. This is particularly important in complex masonry projects where precise adjustments are necessary before the mortar sets.

2. Improved Adhesion HPMC contributes to superior bonding characteristics. The polymer enhances the adhesion of the mortar to various substrates, including bricks, blocks, and tiles. This strong bond is crucial for stability and durability, particularly in challenging environmental conditions.

3. Water Retention HPMC is known for its superior water-retention capabilities. This property ensures that the mortar remains workable for a longer period, allowing it to retain moisture during the curing process. Adequate moisture is essential for the hydration of cement, leading to stronger and more resilient structures.

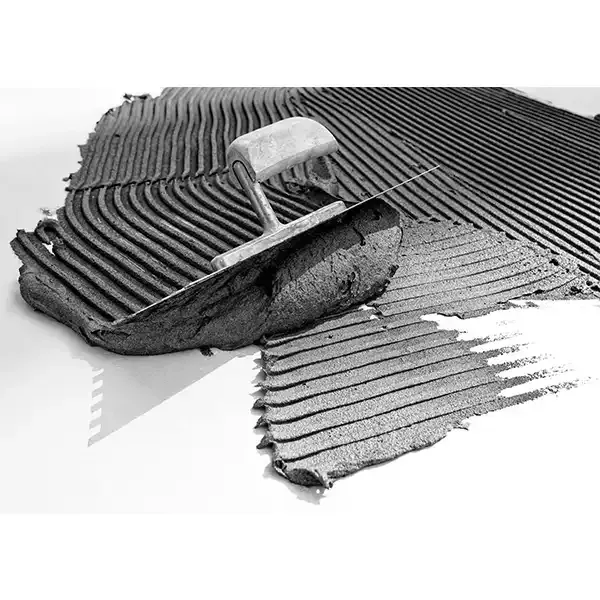

hpmc mortar

4. Versatility HPMC mortar can be used for a variety of construction applications, ranging from tile adhesives to plastering and rendering. This versatility makes it a valuable asset for builders, as it can be applied in numerous scenarios, reducing the need for multiple specialized products.

5. Eco-Friendly Solution As construction moves towards sustainability, HPMC stands out as an eco-friendly material. Being derived from natural sources, it significantly reduces the environmental impact compared to synthetic alternatives. Additionally, HPMC mortars can contribute to energy-efficient building practices, as the improved insulative properties may lead to reduced energy consumption in buildings.

Application Areas

HPMC mortar finds its application in a variety of areas within the construction industry. It is particularly favored in tile installation where its high adhesion and flexibility offer excellent performance. Additionally, its use in interior and exterior wall plastering has garnered positive feedback due to its consistent finish and resistance to cracking.

Future Prospects

As the construction industry adapts to the demands of sustainability, the role of materials like HPMC mortar will continue to expand. Its ability to enhance workability, improve adhesion, and provide environmental benefits will likely see increased adoption. Continuous research and development in polymer technology may also lead to new formulations of HPMC that offer even greater performance benefits.

In conclusion, HPMC mortar is setting a new standard in the construction industry. By incorporating advantageous properties such as enhanced adhesion, improved workability, and excellent water retention, it supports builders in creating durable and sustainable structures. As we move into a new era of construction, materials like HPMC mortar will undoubtedly play a critical role in shaping the future of building practices. Embracing such innovations not only benefits the construction workflow but also aligns with the global movement towards environmentally responsible construction techniques. The future of HPMC mortar looks promising, and as its popularity grows, it will likely become an essential component in modern construction projects worldwide.