- Introduction to PVA polymer price dynamics

- Key Factors Influencing Market Trends

- Technical Advantages of Modern Polymer Powders

- Major Suppliers and Price Comparisons

- Customized Solutions to Meet Industry Demands

- Application Cases Across Different Sectors

- Conclusion: The Future Outlook for pva polymer price

(pva polymer price)

Understanding the Global PVA Polymer Price Movement

The global PVA polymer price landscape has undergone notable changes driven by shifts in raw material costs, industrial demand, and technological innovations. Polyvinyl alcohol (PVA) polymers play a crucial role in various industries, serving as essential additives in construction, adhesives, and textiles. In the first quarter of this year, average pva polymer price ranged between $1,900 and $2,300 per metric ton, according to recent industry data. These figures exhibit a moderate increase compared to last year, highlighting the impact of both supply chain reconfiguration and rising energy costs. With evolving application requirements and regional supply dynamics, understanding pva polymer price fluctuations is vital for stakeholders seeking sustainable procurement strategies.

Key Factors Influencing Market Trends

Several critical factors shape the pricing environment for PVA polymer, redispersible polymer powder, and related compounds. Supply stability, currency fluctuations, and regulatory policies significantly contribute to volatile pricing. Of particular importance is the availability of raw materials such as vinyl acetate monomer, whose cost and quality directly influence the final product. For instance, in Q1 2024, the global average price of vinyl acetate monomer spiked by approximately 8%, contributing to the upward trend in PVA polymer price. Additionally, environmental compliance and technological advancements in powder drying and spray homogenization processes have also played an integral role, enabling improved cost efficiency for manufacturers and enhancing overall market resilience.

Technical Advantages of Modern Polymer Powders

Modern redispersible polymer powder and PVA-based compounds are recognized for their superior dispersibility, water resistance, and strong adhesive properties. These technical improvements have enhanced their suitability in demanding construction operations and high-performance adhesives. Compared to traditional polymer powders, contemporary variants deliver enhanced tensile strength—improvements of up to 20% are noted in reinforced mortars. Furthermore, optimized particle size distribution in advanced polymer powder production contributes to improved workability in tile adhesives and self-leveling compounds, decreasing application time by nearly 15%. Environmental benefits include lower VOC emissions and improved recyclability, catering to an increasingly sustainability-conscious market.

Major Suppliers and Price Comparisons

The competitive landscape features renowned suppliers from Asia, Europe, and North America. Pricing often reflects differences in feedstock sources, technical innovation, and regional logistics. The following table illustrates a comparative overview of polymer powder price in Q2 2024:

| Supplier | Region | PVA Polymer Price (USD/MT) |

Redispersible Polymer Powder Price (USD/MT) |

Lead Time (Days) | Specialization |

|---|---|---|---|---|---|

| Kuraray Co., Ltd. | Japan | 2,250 | 2,550 | 17 | High Purity Grades, Construction |

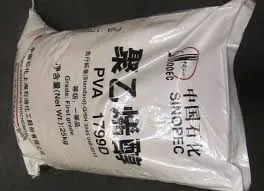

| Sinopec | China | 2,030 | 2,320 | 23 | Cost Leadership, Bulk Supply |

| Wacker Chemie AG | Germany | 2,400 | 2,730 | 12 | High Performance, R&D Focused |

| Celanese Corporation | USA | 2,310 | 2,620 | 15 | Industrial Applications |

From the data, Asian suppliers provide competitive rates with longer lead times, while European and North American companies emphasize performance and shorter delivery cycles. Customers must balance cost considerations with technological performance and supply reliability.

Customized Solutions to Meet Industry Demands

To better serve evolving client requirements, manufacturers now offer tailor-made PVA polymer blends and redispersible polymer powder formulations. Customization may focus on particle size, viscosity range, or reactivity, depending on end-use specifications. In the building materials sector, for example, polymer powder with anti-cracking properties has helped reduce failure rates in exterior wall applications by 25%. Similarly, in textile sizing operations, highly hydrolyzed PVA improves weaving speed and fabric smoothness, leading to a 12% increase in operational efficiency. Such customized approaches are supported by collaborative R&D, ensuring product attributes closely align with project performance targets.

Application Cases Across Different Sectors

The versatility of modern polymer powders and PVA-based blends underpins their adoption across disparate sectors. In the construction industry, redispersible polymer powder is instrumental in producing durable self-leveling floor screeds capable of withstanding over 5 MPa compressive stress. In adhesives, PVA polymer ensures robust bonding in woodworking projects, extending product lifespan by an average of 18%. The pharmaceutical sector leverages the biocompatibility of PVA for tablet coatings, facilitating controlled-release formulations. Case studies demonstrate that integrating advanced polymer powder into cementitious mortars decreases shrinkage by nearly 30%, thereby minimizing repair costs and extending the service life of infrastructure projects. These use cases exemplify the broad spectrum of benefits—mechanical, economic, and environmental—associated with advanced polymer additives.

Conclusion: The Future Outlook for PVA Polymer Price

In summary, pva polymer price and related polymer powder price points remain susceptible to ongoing shifts in supply and demand, technological progress, and regulatory changes. Process innovation and sustainable sourcing will distinguish leading manufacturers in the medium term. Market forecasts predict steady growth for redispersible polymer powder price, underpinned by the rising demand in construction, textiles, and packaging industries worldwide. Stakeholders should monitor not only raw material fluctuations but also strategic investments in next-generation production technologies. Taking a proactive approach will secure both profitability and operational resilience amid a changing industry landscape.

(pva polymer price)

FAQS on pva polymer price

Q: What is the current PVA polymer price per ton?

A: The current PVA polymer price per ton varies between $1,600 and $2,000, depending on quality and region. Prices fluctuate based on raw material costs and global demand.Q: What factors influence the PVA polymer price?

A: Key factors include raw material costs, production capacity, and supply-demand balance. Market trends and transportation costs also impact the final price.Q: How does the redispersible polymer powder price compare to PVA polymer price?

A: Redispersible polymer powder price is generally higher than PVA polymer price due to additional processing. Typically, RDP powder ranges from $2,100 to $2,800 per ton.Q: Where can I find the latest polymer powder price updates?

A: Most manufacturers and chemical trading platforms publish weekly or monthly polymer powder price updates online. Industry reports and market research agencies also provide reliable pricing data.Q: Does buying polymer powder in bulk lower the price?

A: Yes, purchasing polymer powder in larger quantities often results in discounted prices per ton. Bulk orders also offer better negotiation opportunities with suppliers.-

The Application and Significance of Construction RdpNewsMay.19,2025

-

Industrial Grade HpmcNewsMay.19,2025

-

Building Coating Adhesive Building Coating Adhesive HpmcNewsMay.19,2025

-

Application Of Hpmc For Detergent For Detergent In DetergentsNewsMay.19,2025

-

Application Of Hpmc Cellulose In Cement-Based MaterialsNewsMay.19,2025

-

Application Of High Quality Hpmc For Construction In The Field Of ConstructionNewsMay.19,2025