The Role of Cellulose in Paints Enhancing Performance and Sustainability

In the realm of paint formulation, the quest for sustainable and high-performing materials has led to an increased interest in cellulose, a naturally occurring polymer derived from plant cell walls. With its unique properties, cellulose has emerged as an essential component in the paint industry, playing a pivotal role in enhancing paint formulations and contributing to their environmental sustainability.

Understanding Cellulose

Cellulose is the most abundant organic polymer on Earth, consisting of long chains of glucose units linked by β-1,4-glycosidic bonds. As a structural component of plant cell walls, cellulose provides rigidity and strength to plants, making it a reliable source of material for various industrial applications. Its non-toxic nature, biodegradable characteristics, and renewability make cellulose an attractive option for environmentally conscious industries, including paint production.

Cellulose in Paint Formulations

In paint formulations, cellulose serves several critical functions. It acts as a thickening agent, enhancing the viscosity of paint, which contributes to better application properties. This is particularly advantageous for water-based paints, which can sometimes be prone to poor flow and leveling. By incorporating cellulose derivatives, such as hydroxypropyl methylcellulose (HPMC) and carboxymethyl cellulose (CMC), formulators can achieve optimal viscosity without relying heavily on synthetic thickeners.

Furthermore, cellulose enhances the stability of paint emulsions. The presence of cellulose helps to stabilize pigment dispersions, ensuring uniform color distribution and preventing sedimentation. This stability not only improves the aesthetic appeal of the paint but also enhances its overall performance and longevity. The ability of cellulose to form a film upon drying further contributes to the durability and adherence of paint coatings, making it an indispensable ingredient in many formulations.

Enhancing Performance and Application

The multifunctional nature of cellulose makes it a valuable addition to paint formulations. It provides anti-sag properties for thicker coatings, inhibiting the downward flow of paint during application. This is particularly important for vertical surfaces where sagging can lead to unsightly drips and an uneven finish. Additionally, cellulose can improve the open time of paints, allowing for more extended workability before the paint skins over, which is crucial for achieving a smooth, even application.

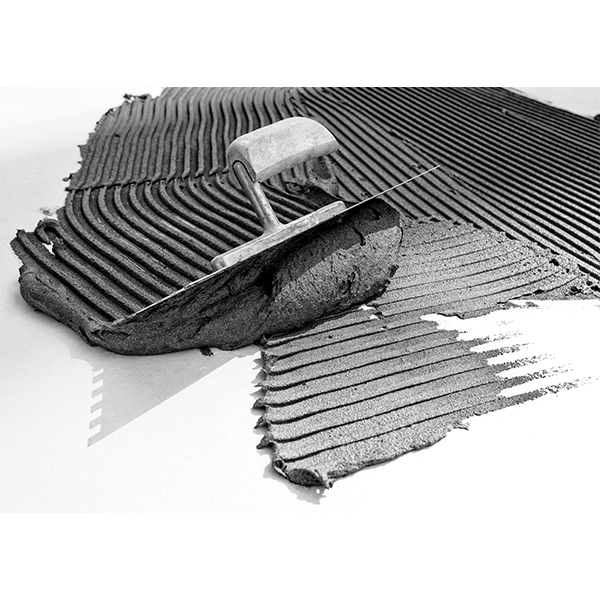

cellulose for paints

Moreover, cellulose can enhance the overall durability of paint. When incorporated into coatings, it can contribute to improved resistance against abrasion, weathering, and other environmental factors. This is particularly relevant for exterior paints, which must endure harsh conditions without deteriorating.

Sustainability and Eco-Friendliness

As the paint industry continues to embrace sustainability, cellulose aligns perfectly with the need for eco-friendly materials. Sourced from renewable biomass, cellulose significantly reduces the carbon footprint associated with paint production. By replacing or reducing the use of petroleum-derived additives, manufacturers can develop more sustainable products that meet growing consumer demand for environmentally responsible choices.

Furthermore, the incorporation of cellulose in paint formulations can enhance biodegradability and reduce the accumulation of harmful substances in the environment. Unlike some synthetic polymers, cellulose-based products can decompose naturally over time, contributing to a circular economy. This aspect is increasingly important as regulations around environmental impact tighten, prompting manufacturers to seek alternative materials that fulfill both performance and sustainability criteria.

Challenges and Future Directions

Despite the numerous benefits, the use of cellulose in paint formulations is not without challenges. Variability in the quality and properties of cellulose derived from different plant sources can affect paint performance. Additionally, the integration of cellulose must be carefully balanced to avoid negative impacts on paint film properties, such as gloss and transparency. Ongoing research and development are crucial to optimize cellulose modifications and formulations to overcome these challenges.

Looking ahead, advancements in cellulose processing and modification could further enhance its role in the paint industry. Innovations such as nanocellulose and bioengineered cellulose derivatives may offer new opportunities for formulators to improve performance while maintaining sustainability.

Conclusion

Cellulose, with its intrinsic properties and sustainability credentials, is becoming an integral part of the modern paint industry. As manufacturers continue to seek environmentally friendly alternatives to traditional additives, cellulose stands out as a versatile ingredient that not only enhances performance but also aligns with the industry's shift towards more sustainable practices. By harnessing the potential of cellulose, the paint industry can not only improve its products but also contribute positively to the environment, paving the way for a greener future.

-

Rdp Powder: Key Considerations for Wholesalers in the Building Materials IndustryNewsJul.08,2025

-

Key Considerations for Wholesalers: Navigating the World of Hpmc - Based ProductsNewsJul.08,2025

-

Hpmc Detergent: Key Considerations for WholesalersNewsJul.08,2025

-

Key Considerations for Wholesalers: China Hpmc For Tile Adhesive, Coating Additives, Concrete Additives, and MoreNewsJul.08,2025

-

Crucial Considerations for Wholesalers: Navigating the World of Construction MaterialsNewsJul.08,2025

-

Key Considerations for Wholesalers Sourcing Additive For Cement, Additive For Concrete, Additive For Putty from Additive Manufacturer Shijiazhuang Gaocheng District Yongfeng Cellulose Co., Ltd.NewsJul.08,2025